Dimmers are an excellent complement for energy-efficient lighting. They can be used to lower the lighting output when daylight is available, thus reducing energy expenses. In addition, they can be used to “set the mood” in locations like restaurants and event venues, where occupants often prefer lower lighting levels. Homeowners can also use dimmers to make their lighting more personal; for example, they can be used to reduce ambient lighting while watching TV.

However, before purchasing any dimmer, it is important to understand that they are not universal products intended for any type of lighting. Although some dimming systems are intended for many types of light bulbs, there are also dimmers that will only work with certain lighting technologies or above a specified wattage.

Types of Dimmers

Dimming controls can be classified into three main types: forward-phase dimming, reverse-phase dimming and 4-wire dimming (also known as 0-10V). This section will provide a brief overview of each type.

1) Forward-Phase Dimmers

Forward-phase dimmers achieve their brightness reduction effect by removing the leading portion of the voltage wave during each half-cycle, as shown below. Note that this reduces the total power delivered to the lamp, but the voltage magnitude is not changed.

The advantage of this dimming method is that it only requires two wires, making it easy to integrate with existing installations. This dimming method was originally designed for use with incandescent (120V) lighting fixtures, and has evolved for use with other types of lighting loads, including magnetic low voltage (MLV) transformers and some types of LED drivers. However, note how voltage is applied suddenly each half-cycle, and this can be very demanding for electronic circuitry, potentially shortening the service life of drivers.

Forward phase dimmers are also known as incandescent dimmers, leading-edge dimmers, triac dimmers or SCR dimmers (silicon-controlled rectifier).

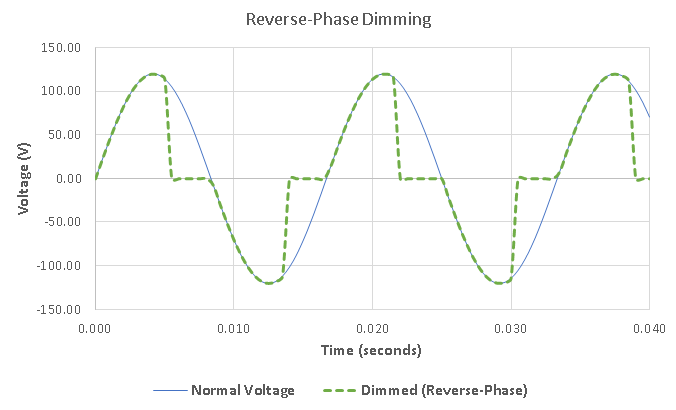

2) Reverse-Phase Dimmers

The basic principle is similar to forward-phase dimming, but this type of dimmer cuts off the trailing edge of the voltage waveform, as shown below. The effect is the same - a reduction of power consumption while conserving the voltage.

This dimming technology also uses two wires, and was originally designed to control electronic low voltage (ELV) transformers used in low-voltage applications (12V). Reverse-phase dimmers are also known as electronic low voltage (ELV) and trailing-edge dimmers.

3) 4-Wire (0-10V) Dimming

4-wire (0-10V) dimmers have been used for years in commercial applications for fluorescent lighting, also along with occupancy and daylight sensor systems. They are now becoming a popular choice for LED products. 4-wire dimmers use two control lines and two power connections, and they modulate the power supply in response to the control signal, hence their name. These dimmers are also known as fluorescent dimmers or low-voltage dimmers.

Dimmer Selection

There are several important factors to consider before purchasing a dimmer, to ensure you get compatibility and optimal performance.

- Lighting source: lamp wattage and type

- Control method

- Operating requirements: 1-pole, 3-way, 4-way, multi-location, etc.

- Compatibility: Make sure that the lights are dimmable, by checking their cut sheets.

Consider that dimmers have a specified power rating, which determines the load they can handle. When adding the total lighting load connected to it, do not forget the ballast losses:

- Magnetic low voltage (MLV) transformers dissipate up to 20% of the connected load as heat, and this must be considered when selecting dimmer capacity.

- Electronic low voltage (ELV) transformers have a much lower heat dissipation, but it also counts towards the required dimmer capacity.

Incompatible Lighting and Dimmers: Common Issues

If you connect a dimmer and a lighting fixture that are not designed to operate together, you will have performance issues. The lamps may work incorrectly or not at all, and in the worst-case scenario you may end up damaging the dimmers or lighting fixtures. The following table summarizes the most common issues when lighting fixtures and dimmers do not match.

|

Performance Issue |

Description |

|

1) Flickering |

Lamps turn on and off repeatedly. |

|

2) Drop out |

No lighting output at the end of the dimmer scale. |

|

3) Dead travel |

Adjusting the dimmer does not change the lighting output. |

|

4) Not smooth |

Light output does not go from dim to bright linearly. |

|

5) Multiple lamp issues |

Performance issues arise when multiple lamps are added |

|

6) Damage or failure |

Can affect the dimmer, lamps or ballasts/drivers |

|

7) Load below minimum |

Lamp power is below the minimum required by the dimmer, common with LED due to its low consumption. |

Be careful when using the same dimmer with many LED fixtures. There are many LED driver configurations, and there is a chance that not all of them will be compatible with the same dimmer. Some issues are not apparent when different LED products share a circuit, only becoming evident once a dimmer is added - verify dimmer compatibility with all lighting products involved to prevent this.

Concluding Remarks

LED lighting upgrades are excellent from the investment standpoint, but they can achieve even higher performance if complemented with dimmers. Keep in mind that large NYC buildings must upgrade their lighting systems to meet the Energy Conservation Code by 2025, according to Local Law 88 of 2009. If your property is subject to this law, the lighting upgrade represents a great chance to also deploy dimmers.