Backflow Preventer Design

5 Days- That's a Lightning Fast Turnaround Time!

1

Upload Files and Pay

Upload PDF or CAD files, and pay to start the process. An engineer is auto-assigned to your project.

2

Document Review

An engineer will review all the documents shared and connect with you if anything else is required. Initial work starts.

3

Work Starts

Actual design/ report creation work begins.

4

Quality Check

The design and report are checked by the project manager to make sure 100% quality work is delivered.

5

Delivery

The design/ report is delivered to you.

NEED HELP OR ADDITIONALINFORMATION?

C A L L U S N O W

(646) 776-4010Get Backflow Preventer Design Services In 3 Easy Steps

0%

Get the DEP and DOB approval

All in One Go

Designs with no errors

100% Precision

Get the BFP design within

5 Days

Compact and cost efficient design with BFP suggestion

Save Cost

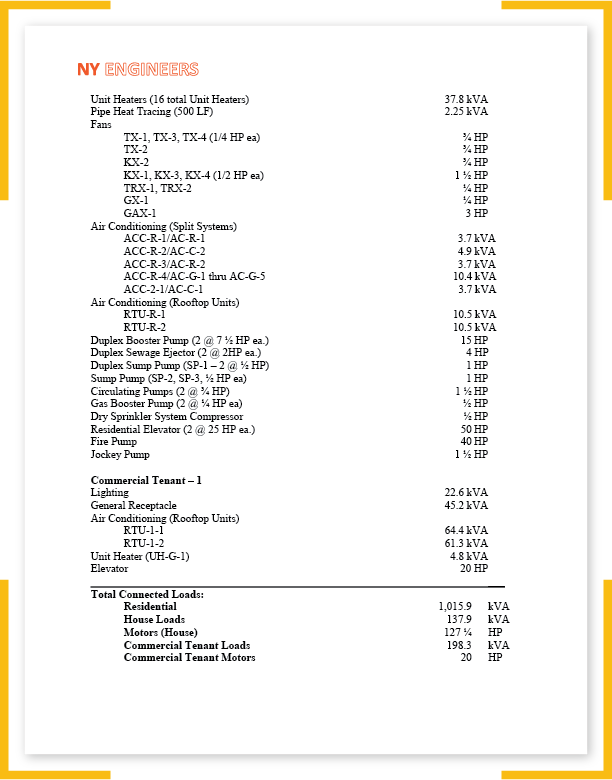

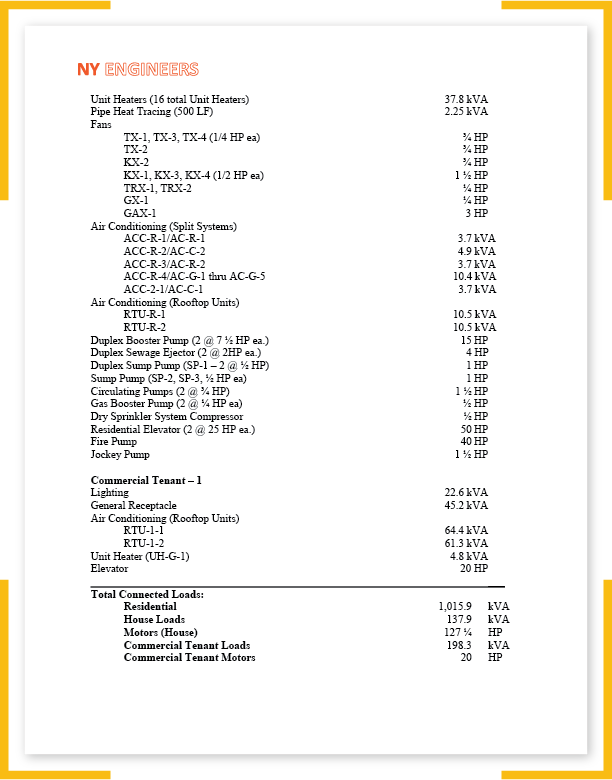

$ 1250

Backflow Preventer

Documents Required

Floor plan in CAD, BFP room markup, and building occupancy details.

Delivery Time & Standards

We deliver your design (digitally) within 5 business days as per NYC DEP standards.

What's not Covered

This service does not cover site visits, stamping, DOB/DEP filing, and more than 2 minor iterations.

Service Constraint

The service fee is restricted to per service (domestic/fire) and does not include filing charges.

$1250*

Backflow Preventer

Get your backflow preventer design at lightning speed.

Compact and cost-efficient designs with BFP suggestions.

Designs with no errors.

Get your DEP and DOB approval.

Backflow Preventer

Protect Your Drinking Water Supply

When there are pressure changes in your plumbing system, a backflow preventer keeps harmful substances out of the water supply.

Meet Codes and Avoid Penalties

Design and install a backflow preventer as required by your city and state codes. Avoid fines and service interruptions.

Design & Approval at Fixed Price

We offer an approved backflow preventer design at fixed price - avoid hidden fees and stay within your design budget.

Our on-demand engineering expert

Still not sure about how to proceed?

YOU CAN WRITE TO ME AT inquiry@ny-engineers.com

When a plumbing system is operating normally, water only flows in one direction - from the local supply to individual fixtures, and then to the sewer system. However, there are events and operating conditions that create pressure differences opposite to the intended flow direction. Unless a plumbing installation has adequate prevention measures, this will result in backflow.

A backflow preventer only allows water movement in one direction, as intended in the plumbing design, blocking off water flow when the downstream pressure is higher.

Under the US EPA Safe Drinking Water Act (SDWA), water suppliers are responsible for quality at the source. However, after water has been delivered to a building, the owner is responsible for preventing contamination of the source. Backflow prevention is especially important in metropolitan areas that are densely populated, such as New York City and Chicago. If backflow is allowed to happen, there is a high chance that someone in your building or a neighboring property will be exposed to contaminated water. Backflow preventers must be tested and serviced regularly to ensure a correct operation.

When backflow is not controlled properly in a building, the drinking water supply can be contaminated with hazardous substances and waste. This can affect not only occupants in the building, but also neighboring properties that use the same water service. In general, backflow will occur when there is a reverse pressure in the plumbing system, and no devices to prevent water movement. There are two ways this can happen - backsiphonage and backpressure.

Backsiphonage occurs when water pressure is lowered upstream, creating a pressure difference that pulls water towards the source. This is often caused by fractured or undersized pipes, especially when water consumption is high. Back siphonage can also occur when fire hydrants are opened, causing the water supply pressure to drop suddenly.

Backpressure occurs when water pressure is raised downstream. Just like back siphonage, this condition creates a pressure difference towards the water supply. Back pressure can be produced by gravity in high-rise buildings, and by pressurized installations such as automatic sprinkler systems.

A cross-connection can be defined as any existing or possible connection between the water supply and a non-potable fluid, such as greywater or blackwater. Cross-connections can be created temporarily by accident, but they also exist permanently in some plumbing installations.

Temporary cross-connections are normally created when plumbing fixtures are submerged in water. For example, this can happen if you have a pulldown faucet in a kitchen, and you fill the sink while the faucet is extended. Cross-connections are also created during extreme weather events that cause flooding, since plumbing fixtures are submerged.

Permanent cross-connections are necessary in some installations, and removing them is not an option - only a backflow preventer can protect the water supply in these cases. The applications in which cross-connections are needed include fire sprinkler systems, swimming pools, irrigation systems and beverage production equipment.

All backflow preventers have the same general purpose. However, there are many types available, each designed for specific applications:

|

Type of Backflow Preventer |

Standard |

Operating Principle |

|

Reduced Pressure Backflow Assembly |

ASSE 1013 |

Two independent check valves with a vented intermediate chamber. |

|

Double Check Valve Assembly |

ASSE 1015 |

Two independent check valves. |

|

Pressure Vacuum Breaker |

ASSE 1020 |

One check valve, and one air inlet valve downstream of the check valve. |

|

Reduced Pressure Detector Assembly |

ASSE 1047 |

Two independent check valves with a hydraulically operated venting chamber, and a bypass line that indicates leakage or unauthorized water use (visual or audible). |

|

Double Check Detector Assembly |

ASSE 1048 |

Two independent check valves, and a bypass line that indicates leakage or unauthorized water use (visual or audible). |

|

Spill Resistant Vacuum Breaker |

ASSE 1056 |

Similar to a pressure vacuum breaker, with the addition of a spill prevention device. |

New York Engineers can select the best type of backflow preventer for your building, based on the specific application and the operating conditions of your plumbing system. Depending on how your installation is designed, more than one backflow preventer may be needed. For example, buildings with multiple service lines must install one backflow preventer for each line.

Backflow prevention systems can be designed for indoor, outdoor or below-grade installations. There are horizontal and vertical configurations available, but horizontal backflow preventers are the most common.

Backflow preventers are mandatory for most buildings in NYC, and there are few exceptions. Building owners can be fined for not having a backflow preventer, and their water service may be interrupted by the NYC Department of Environmental Protection (DEP).

The DEP provides 1 billion gallons of drinking water to 8.6 million people each day, and water quality is a top priority for them. The DEP conducts 650,000 drinking water tests each year, and their requirements for backflow preventers are very stringent.

- If you do not have a backflow preventer in a property where the device is mandatory, and the DEP finds out, you will receive an order to install one.

- Once you receive the installation order, you have 30 days to comply before getting a Notice of Violation (NOV).

- However, you will not get the NOV if the installation is already in process by the deadline. In this case, the DEP must receive a written certification from a Licensed Master Plumber or Registered Design Professional.

To install a backflow preventer in NYC, you must complete the following steps:

- A New York State Registered Architect or Professional Engineer must submit a backflow prevention plan for approval by the DEP.

- After the DEP approves the plan, you must hire a Licensed Master Plumber (LMP) to install the backflow preventer.

- Finally, the system must be tested by a NYS Certified Backflow Prevention Device Tester (some LMPs are also certified testers).

- The test report must be submitted to the DEP within 30 days after installing the backflow preventer. The report must be signed by an LMP, and by the Registered Design Professional who submitted the plan for approval.

Once the backflow preventer is installed and operational, it must be tested again once per year. The NYC DEP will issue a Notice of Violation (NOV) if the annual test is missed, and building owners face a penalty of up to $500 per each untested device. However, the DEP will send an email notification to remind you of the annual report. You must hire a certified tester like in the initial procedure, but this report only requires the signature of an LMP.

The DEP makes building owners responsible for installing backflow preventers and providing adequate maintenance. In other words, the responsibility cannot be passed on to tenants. Facilities with a single domestic service can apply for a backflow preventer exemption, and the corresponding application must be filled and submitted by a Professional Engineer (PE) or Registered Architect (RA).

As mentioned above, the NYC DEP takes water quality very seriously. They have an extensive list of building types where backflow preventers are mandatory, and it covers most residential and commercial properties. The following are some of the buildings covered, and you can check the full list by visiting the DEP Backflow Preventer FAQ webpage:

- Laundries and dry cleaners

- Carwashes

- Greenhouses

- Hospitals

- Medical and dental offices

- Food processing facilities

- Auto repair shops

- Sewage treatment plants

- Properties with roof tanks

- Supermarkets

- Schools and colleges

- Barber shops and beauty salons

- Properties with commercial kitchens

- Properties with water-cooled equipment

- Properties with groundwater wells

- Properties with ground-based irrigation systems

- Properties with swimming pools

- Properties with multiple water service lines

- Properties with boiler systems that use water treatment chemicals

As you can see, most commercial building types are covered, and this is not the full list. In other words, backflow preventers are mandatory for most NYC buildings.

The exact cost of a backflow prevention system will depend on the specific application and the size of your building. However, the NYC DEP provides the following cost guidelines:

|

Building Size |

Examples |

Typical Cost |

|

Very small |

1-story constructions |

$3,000 - $5,000 |

|

Small |

2-story constructions |

$3,750 - $5,500 |

|

Small to mid-size |

Carwashes, small manufacturing facilities, laundry / dry cleaning |

$5,000 - $7,000 |

|

Mid-size |

Offices, department stores, large manufacturing facilities |

$7,500 - $13,000 |

|

Large |

High-rise constructions and hospitals |

$14,000 - $34,000 |

At New York Engineers, we design backflow prevention systems that meet DEP requirements at an optimal cost. After the installation, we will provide you with all the drawings and documents necessary for future reference.

Our company has a solid reputation and vast track record with both residential and commercial clients. We have experience in all areas of MEP design, and this includes backflow prevention systems. If you have recently received an installation order from the NYC DEP, we can help you meet the 30-day deadline and avoid a Notice of Violation.

We combine our MEP expertise with the latest engineering software, and our designs have an 80% first time approval rate with the NYC Department of Buildings and other local authorities. We also offer a zero change order guarantee when you work with one of our certified contractors.

Importance of Backflow Preventers in Plumbing Design

When a plumbing system is operating normally, water only flows in one direction - from the local supply to individual fixtures, and then to the sewer system. However, there are events and operating conditions that create pressure differences opposite to the intended flow direction. Unless a plumbing installation has adequate prevention measures, this will result in backflow.

A backflow preventer only allows water movement in one direction, as intended in the plumbing design, blocking off water flow when the downstream pressure is higher.

Under the US EPA Safe Drinking Water Act (SDWA), water suppliers are responsible for quality at the source. However, after water has been delivered to a building, the owner is responsible for preventing contamination of the source. Backflow prevention is especially important in metropolitan areas that are densely populated, such as New York City and Chicago. If backflow is allowed to happen, there is a high chance that someone in your building or a neighboring property will be exposed to contaminated water. Backflow preventers must be tested and serviced regularly to ensure a correct operation.

Why Backflow Is a Major Health Hazard

When backflow is not controlled properly in a building, the drinking water supply can be contaminated with hazardous substances and waste. This can affect not only occupants in the building, but also neighboring properties that use the same water service. In general, backflow will occur when there is a reverse pressure in the plumbing system, and no devices to prevent water movement. There are two ways this can happen - backsiphonage and backpressure.

Backsiphonage occurs when water pressure is lowered upstream, creating a pressure difference that pulls water towards the source. This is often caused by fractured or undersized pipes, especially when water consumption is high. Back siphonage can also occur when fire hydrants are opened, causing the water supply pressure to drop suddenly.

Backpressure occurs when water pressure is raised downstream. Just like back siphonage, this condition creates a pressure difference towards the water supply. Back pressure can be produced by gravity in high-rise buildings, and by pressurized installations such as automatic sprinkler systems.

Preventing Backflow: The Role of Cross-Connections

A cross-connection can be defined as any existing or possible connection between the water supply and a non-potable fluid, such as greywater or blackwater. Cross-connections can be created temporarily by accident, but they also exist permanently in some plumbing installations.

Temporary cross-connections are normally created when plumbing fixtures are submerged in water. For example, this can happen if you have a pulldown faucet in a kitchen, and you fill the sink while the faucet is extended. Cross-connections are also created during extreme weather events that cause flooding, since plumbing fixtures are submerged.

Permanent cross-connections are necessary in some installations, and removing them is not an option - only a backflow preventer can protect the water supply in these cases. The applications in which cross-connections are needed include fire sprinkler systems, swimming pools, irrigation systems and beverage production equipment.

The Types of Backflow Preventer We Design

All backflow preventers have the same general purpose. However, there are many types available, each designed for specific applications:

|

Type of Backflow Preventer |

Standard |

Operating Principle |

|

Reduced Pressure Backflow Assembly |

ASSE 1013 |

Two independent check valves with a vented intermediate chamber. |

|

Double Check Valve Assembly |

ASSE 1015 |

Two independent check valves. |

|

Pressure Vacuum Breaker |

ASSE 1020 |

One check valve, and one air inlet valve downstream of the check valve. |

|

Reduced Pressure Detector Assembly |

ASSE 1047 |

Two independent check valves with a hydraulically operated venting chamber, and a bypass line that indicates leakage or unauthorized water use (visual or audible). |

|

Double Check Detector Assembly |

ASSE 1048 |

Two independent check valves, and a bypass line that indicates leakage or unauthorized water use (visual or audible). |

|

Spill Resistant Vacuum Breaker |

ASSE 1056 |

Similar to a pressure vacuum breaker, with the addition of a spill prevention device. |

New York Engineers can select the best type of backflow preventer for your building, based on the specific application and the operating conditions of your plumbing system. Depending on how your installation is designed, more than one backflow preventer may be needed. For example, buildings with multiple service lines must install one backflow preventer for each line.

Backflow prevention systems can be designed for indoor, outdoor or below-grade installations. There are horizontal and vertical configurations available, but horizontal backflow preventers are the most common.

Installing a Backflow Preventer in New York City

Backflow preventers are mandatory for most buildings in NYC, and there are few exceptions. Building owners can be fined for not having a backflow preventer, and their water service may be interrupted by the NYC Department of Environmental Protection (DEP).

The DEP provides 1 billion gallons of drinking water to 8.6 million people each day, and water quality is a top priority for them. The DEP conducts 650,000 drinking water tests each year, and their requirements for backflow preventers are very stringent.

- If you do not have a backflow preventer in a property where the device is mandatory, and the DEP finds out, you will receive an order to install one.

- Once you receive the installation order, you have 30 days to comply before getting a Notice of Violation (NOV).

- However, you will not get the NOV if the installation is already in process by the deadline. In this case, the DEP must receive a written certification from a Licensed Master Plumber or Registered Design Professional.

To install a backflow preventer in NYC, you must complete the following steps:

- A New York State Registered Architect or Professional Engineer must submit a backflow prevention plan for approval by the DEP.

- After the DEP approves the plan, you must hire a Licensed Master Plumber (LMP) to install the backflow preventer.

- Finally, the system must be tested by a NYS Certified Backflow Prevention Device Tester (some LMPs are also certified testers).

- The test report must be submitted to the DEP within 30 days after installing the backflow preventer. The report must be signed by an LMP, and by the Registered Design Professional who submitted the plan for approval.

Once the backflow preventer is installed and operational, it must be tested again once per year. The NYC DEP will issue a Notice of Violation (NOV) if the annual test is missed, and building owners face a penalty of up to $500 per each untested device. However, the DEP will send an email notification to remind you of the annual report. You must hire a certified tester like in the initial procedure, but this report only requires the signature of an LMP.

The DEP makes building owners responsible for installing backflow preventers and providing adequate maintenance. In other words, the responsibility cannot be passed on to tenants. Facilities with a single domestic service can apply for a backflow preventer exemption, and the corresponding application must be filled and submitted by a Professional Engineer (PE) or Registered Architect (RA).

Building Types That Require a Backflow Preventer in NYC

As mentioned above, the NYC DEP takes water quality very seriously. They have an extensive list of building types where backflow preventers are mandatory, and it covers most residential and commercial properties. The following are some of the buildings covered, and you can check the full list by visiting the DEP Backflow Preventer FAQ webpage:

- Laundries and dry cleaners

- Carwashes

- Greenhouses

- Hospitals

- Medical and dental offices

- Food processing facilities

- Auto repair shops

- Sewage treatment plants

- Properties with roof tanks

- Supermarkets

- Schools and colleges

- Barber shops and beauty salons

- Properties with commercial kitchens

- Properties with water-cooled equipment

- Properties with groundwater wells

- Properties with ground-based irrigation systems

- Properties with swimming pools

- Properties with multiple water service lines

- Properties with boiler systems that use water treatment chemicals

As you can see, most commercial building types are covered, and this is not the full list. In other words, backflow preventers are mandatory for most NYC buildings.

How Much Does a Backflow Preventer Cost?

The exact cost of a backflow prevention system will depend on the specific application and the size of your building. However, the NYC DEP provides the following cost guidelines:

|

Building Size |

Examples |

Typical Cost |

|

Very small |

1-story constructions |

$3,000 - $5,000 |

|

Small |

2-story constructions |

$3,750 - $5,500 |

|

Small to mid-size |

Carwashes, small manufacturing facilities, laundry / dry cleaning |

$5,000 - $7,000 |

|

Mid-size |

Offices, department stores, large manufacturing facilities |

$7,500 - $13,000 |

|

Large |

High-rise constructions and hospitals |

$14,000 - $34,000 |

At New York Engineers, we design backflow prevention systems that meet DEP requirements at an optimal cost. After the installation, we will provide you with all the drawings and documents necessary for future reference.

Why Choose NY Engineers

Our company has a solid reputation and vast track record with both residential and commercial clients. We have experience in all areas of MEP design, and this includes backflow prevention systems. If you have recently received an installation order from the NYC DEP, we can help you meet the 30-day deadline and avoid a Notice of Violation.

We combine our MEP expertise with the latest engineering software, and our designs have an 80% first time approval rate with the NYC Department of Buildings and other local authorities. We also offer a zero change order guarantee when you work with one of our certified contractors.