Our HVAC solutions are designed to ensure optimal comfort, regardless of outdoor temperatures.

We identify & eliminate unnecessary energy consumption, leaving you with maximal functionality for the minimum annual energy cost.

All of our systems are designed with longevity in mind, saving you maintenance costs down the line.

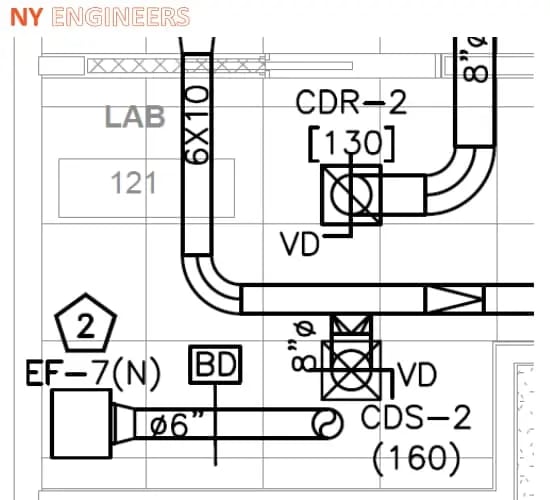

A laboratory exhaust and ventilation system are designed to provide a safe, healthy and clean environment for those professionals using hazardous materials in their experimentation and work. Like any exhaust system, the laboratory exhaust system can be designed and structured to meet the needs and specifications of both large and small layouts. Working with a qualified MEP Engineer like NY Engineers will ensure that your laboratory exhaust system meets success by including consideration in both the design and build of a laboratory setting.

We are one of the fastest growing MEP design firms in the construction industry. We pride ourselves on having a fast turnaround while providing cost effective solutions. We are licensed in 50 states and are your one stop shop for all MEP design needs.

We are licensed in all 50 states!

We design to the perfection

Enjoy our lightening fast turnaround

We have completed so far!

Our designs are approved by DOB in one go

The best service experience in the market

A laboratory exhaust and ventilation system are designed to provide a safe, healthy and clean environment for those professionals using hazardous materials in their experimentation and work. These workers include scientists, laboratory workers, and other professionals that conducting experiments in a professional lab setting. Like traditional exhaust systems the work of the laboratory exhaust system to so clear the lab air of toxins and residual chemical fumes while ensuring they are disposed of in a safe manner while also returning clean air to this lab environment.

Like any exhaust system, the laboratory exhaust system can be designed and structured to meet the needs and specifications of both large and small layouts. Working with a qualified MEP Engineer will ensure that your laboratory exhaust system meets success by including consideration in both the design and build of a laboratory setting. The safety of both the building inhabitants in both the lab and adjacent buildings is paramount therefore ensuring that your design is ideal for your lab's needs is beyond imperative and will impact the overall operating costs of the building.

By choosing the proper system for your space, you will be able to positively impact operation costs by increasing efficiency and taking the labor off other HVAC equipment to maintain the proper air temperature and air quality in the building. In laboratories it is especially important to maintain air quality and a clean environment. Without the proper mechanical equipment, a laboratory could become unstable or unsafe leading to disastrous consequences.

Most commercial buildings follow a familiar pattern. There are bare rooms, possibly offices, bathroom facilities, kitchen areas, break rooms, conference rooms, and the more spaces like these that are waiting to be finished once the final occupants move in. Other types of commercial buildings like hospitals care facilities, drug manufacturing, and pharmaceutical buildings need specialized infrastructure and mechanical systems to complete their intended functions. Whether these functions have to do with occupancy care, manufacturing, product creation, or testing and analysis of end products, the proper mechanical, electrical, and plumbing equipment must be selected to ensure the safety of the occupants.

With specialty commercial buildings where very specific tasks need to be completed, the mechanical, electrical, and plumbing systems need to match the level of complexity of the building. Where there are things like clean rooms and laboratories in a building, it takes a specialized set of systems to adequately process and manage the building functions. A laboratory has very specialized functions that produce unique and potentially hazardous waste, toxic chemicals, and manufactured pollutants that can create a combustible atmosphere if left unchecked in the laboratory. For this reason it is necessary to design and install the specialized equipment and systems to manage the expulsion and neutralization of these byproducts.

One such system required is the exhaust system. In standard applications you will find exhaust systems in kitchens, bathrooms, and anywhere else potentially hazardous materials can build up in the atmosphere of a structure. Both commercial and residential structures have exhaust systems in various rooms to help expel the byproducts produced by occupant activities through a series of fans, mechanical equipment, filters, blowers, ductwork, and other components that could make up an exhaust system.

Each laboratory will have it's own unique set of system requirements based on what the laboratory is producing and testing in the space. Consulting with an MEP engineer that has specialized knowledge in lab applications is highly recommended. The earlier you can consult with a professional the better. Consulting with a professional early on in the design process will lower your chance of mistakenly selecting the wrong equipment, drastically.

A laboratory exhaust system can exist for many reasons. in order for the laboratory to be in compliance with industry standards and building codes, an exhaust system must be in place before occupancy and use. The laboratory exhaust system essentially keeps the lab safe, the lab workers safe, and maintains a clean environment for experiments.

Since the chemical fume hood is the most utilized application of laboratory exhaust systems we will focus on them. Here are the main considerations for why you need chemical fume hood into your laboratory design plans:

Additionally, without the proper laboratory exhaust system in place, the construction project will not have a passing inspection from the building inspector. This means an occupancy permit will not be issued until the building code violations have been addressed and fixed. The importance of a laboratory exhaust system cannot be stressed enough. Your MEP engineer will be able to help you understand better why a laboratory exhaust system is required for laboratories.

There are many reasons a fume hood might malfunction or fail overall. Here are the most reported reasons for mechanical failure :

Other reasons for mechanical failures could be user error, lack of maintenance, accidental damage due to an accident in the lab, plus a multitude of other possibilities. The trick is to know your system inside and out so that when a failure does occur, you can assist in the diagnostic activities of the contractor sent to fix the system.

As you can imagine, not just any contractor can work on these types of systems. In order to be able to properly diagnose and repair the system, it must be a specialized mechanical contractor who does the work. Be sure to check the references and qualifications of the companies who will be installing, repairing, or maintaining the system.

Laboratory exhaust system maintenance is paramount to the overall life of the system. Maintaining cleanliness and system health is the only way to ensure the system is adequately able to complete it's function to maintain the atmosphere in the lab. The safety of the occupants is dependent on the exhaust system being able to do clean the air and expel the contaminated air before it has time to build up to unsafe levels.

While some laboratory exhaust systems are designed to meet specific design specifications of a unique build most laboratory exhaust systems can be categorized into three main groups. These categories represent the broadest of ranges of exhaust systems. Your specific laboratory design may require a custom or otherwise unique configuration to meet the project objectives.

Laboratory exhaust systems fall into three main classes:

Let’s take some time to examine each one of these exhaust applications and discuss the proper considerations for each. Understanding each type will help you discuss more intelligently your options with your MEP engineer. A specialized MEP engineer is one of the professionals you should be consulting in the design phase of your project. Getting their input early on in the project will help you avoid costly errors and project deadline delays.

The Chemical Fume Hood is specifically designed to remove hazardous chemicals. Depending on the laboratory environment there can be vapors, unsavory dust, or unstable aggressive solvents or corrosive acids and bases that will need to be dealt with and removed. This piece of ventilation equipment is designed to pull and draw air away from the laboratory worker. The air is pulled across the work surface and through ductwork where it is diluted and released into the atmosphere.

Biological safety hoods/containers are specifically engineered to provide environmental, workers and product protection. Depending on the scientific research being performed there are a variety of biological safety hoods or biosafety cabinets. The biological safety hoods are broken down into classes which determine the specific time of exhaust and protection needed.

“Class I exhausts have an open front, operate under negative pressure and do not provide product protection.”

“Class II is broken down into two main categories—Type A or Type B.

Standard exhaust hoods are traditionally employed in machine shops or mechanical production areas. These are the most basic of the exhaust systems and are designed to remove heat and dust from the environment and keep employees safe while maintaining homeostasis of the production environment. Recognize that you may need much more specialized equipment to complete your mechanical, electrical, plumbing design for your specific laboratory.

382 NE 191st St , Suite 49674

Miami, Florida 33179551 Fifth Avenue, 9th Floor

New York, NY 10176