What is a Hot Gas Reheat & How is it Configured in a System?

When it comes to efficient humidity control and energy-saving HVAC systems, Hot Gas Reheat (HGRH) shines as an innovative technology.

This feature transforms what would otherwise be wasted heat into a resource for reheating air, providing both comfort and energy efficiency.

But what exactly is a hot gas reheat, and how does it work?

This blog unpacks its function, configuration, and benefits, along with current trends in its use.

What is Hot Gas Reheat?

Hot Gas Reheat (HGRH) is an energy-efficient method used in HVAC systems for dehumidification and temperature control.

Instead of relying on separate electric or gas reheat systems, HGRH reuses the heat from a cooling process to slightly warm cooled air before distributing it into a room.

This process ensures comfort while maintaining optimal humidity levels.

Why is Hot Gas Reheat Important?

To maintain comfortable indoor air quality, most HVAC systems lower the air temperature to remove moisture.

However, this can make the air uncomfortably cold. Hot gas reheat solves this by using reclaimed waste heat to reheat the air, creating the perfect balance between temperature and humidity.

Key Benefits:

- Energy Efficiency: Eliminates reliance on secondary heaters by reusing waste heat.

- Better Comfort: Provides reheated air, keeping spaces comfortable without overcooling.

- Improved Indoor Air Quality: Maintains humidity at levels that reduce respiratory issues and prevent mold growth.

- Cost Savings: Reduces operational costs in comparison to traditional electric or gas-powered reheat systems.

As per Trane newsletter, hot gas reheat improves humidity control by reusing compressor-generated heat. This approach enhances comfort while reducing energy waste and energy cost.

How Does Hot Gas Reheat Work?

The process behind hot gas reheat may sound complex, but it can be summarized in four straightforward steps:

- Hot Gas Extraction

The refrigerant comes out of the compressor as a high-temperature gas.

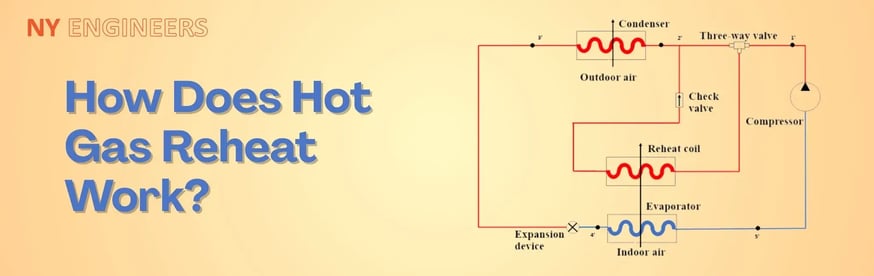

- Three-Way Valve Operation

A three-way valve diverts a portion of the hot refrigerant gas to the reheat coil. The remaining refrigerant proceeds to the condenser as usual.

- Reheat Coil Process

The diverted hot gas flows through the reheat coil, warming the dehumidified air before it is released into the living space.

- Return Path

A check valve ensures that the reheated refrigerant does not flow back into the condenser, maintaining operational efficiency.

Hot Gas Reheat System Configuration

Configuring an HGRH system for optimal performance requires careful design and precise installation.

Components such as three-way valves, reheat coils, and check valves must be strategically placed and calibrated.

Another factor is ensuring a proper balance between the cooling and reheating processes to avoid energy losses.

Key Features of Configuration:

- Modulating Hot Gas Reheat

Advanced systems allow precise control, enabling variable levels of reheating based on indoor conditions.

- Integration with Rooftop Units

HGRH is often incorporated into HVAC rooftop units. These systems feature integrated reheat coils for seamless operation.

- Enhanced Controllers

Modern setups integrate IoT-based controllers for real-time monitoring and adjustments.

For expertise on integrating hot gas reheat coils in professional HVAC designs, explore our solutions.

Comparing Hot Gas Reheat and Traditional Electric Reheat

When choosing between a hot gas reheat coil and traditional electric reheat systems, energy efficiency and functionality become the deciding factors.

By opting for HGRH, HVAC system owners can balance operational costs with eco-conscious energy practices.

Where is Hot Gas Reheat Used?

HGRH systems cater to a wide range of applications, particularly in environments where humidity control and comfort are critical.

Common Applications:

- Healthcare Facilities

Ensures stable humidity levels in sensitive areas like operating rooms and patient wards.

- Laboratories and Art Storage

Offers precise humidity control to protect delicate specimens and artifacts.

- Hospitality

Frequently used in hotels to maintain guest comfort by delivering cool, dry air.

- Retail Spaces and Grocery Stores

Keeps air quality optimal, especially in spaces with high outdoor air intake.

- Fitness Centers

Effective in managing fluctuating occupancy while maintaining user comfort.

Latest Trends in Hot Gas Reheat Technology

With growing concerns about energy efficiency and sustainability, the HVAC industry is consistently improving upon HGRH technology. These new advancements have made systems even more effective.

Trending Innovations:

- Smart Controls

Integration with building automation systems allows dynamic adjustments for energy savings.

- Eco-Friendly Refrigerants

Transitioning to greener refrigerants, such as R-32, increases sustainability.

- Energy Metrics

Systems now come equipped with data analytics to provide insights into energy consumption and cost savings.

- Decentralized Units

Compact HGRH units are being developed for retrofitting in smaller buildings without centralized HVAC systems.

Making the Switch to Hot Gas Reheat

Whether you're considering a new installation or an upgrade to your existing HVAC system, transitioning to an HGRH system can offer long-term savings alongside improved indoor comfort and air quality.

Are you unsure about implementing this system in your project? Connect with NY Engineers for expert advice and HVAC design services.

Keith Fink

Keith is the Franchise Brand Manager at NY Engineers, Keith is all things related to our project portfolio, brands and all things you need to know before we start your project.

Join 15,000+ Fellow Architects and Contractors

Get expert engineering tips straight to your inbox. Subscribe to the NY Engineers Blog below.