Boiler Replacement

5 Days- That's a Lightning Fast Turnaround Time!

1

Upload Files and Pay

Upload PDF or CAD files, and pay to start the process. An engineer is auto-assigned to your project.

2

Document Review

An engineer will review all the documents shared and connect with you if anything else is required. Initial work starts.

3

Work Starts

Actual design/ report creation work begins.

4

Quality Check

The design and report are checked by the project manager to make sure 100% quality work is delivered.

5

Delivery

The design/ report is delivered to you.

NEED HELP OR ADDITIONALINFORMATION?

C A L L U S N O W

(646) 776-4010Get Your Boiler Replacement In 3 Easy Steps

0%

Error free design that matches your requirements

0 Errors

Get improved performance with no emission

0 Emission Performance

Get approval from DOB and other agencies

All in one Go

Improve efficieny and save upto 50% cost

Save Cost

$ 1000

Boiler Replacement

Documents Required

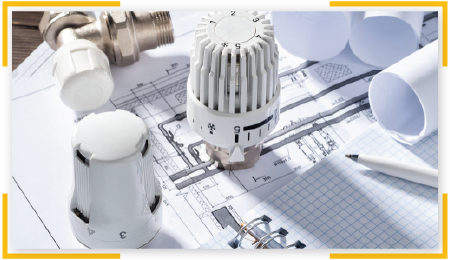

Existing boiler room plans in CAD, boiler layout plan/markup & photos.

Delivery Time & Standards

We deliver your report (digitally) within 5 business days as per Local/IBC standards.

What's not Covered

This service does not cover site visits, stamping, DOB/DEP filing, and more than 2 minor iterations.

Service Constraint

The service fee is applicable for per boiler and boiler room design.

$1000*

Boiler Replacement

Get improved performance with no emission.

Error-free design that matches your requirements.

Improve efficiency and save up to 50% on cost.

Get approval from DOB and other agencies.

Boiler Replacement to Improve Performance

Code compliant design

We design all boiler replacements according to well-established ASME, state, and local authority codes to ensure 100% compliance.

Improve Energy-Efficiency

Upgrade with an energy-efficient system that has a high AFUE ratio that will improve building performance and lower maintenance costs.

Reduce Running Costs

Replace your boiler with a model that uses a more cost-effective fuel type and redesign the system to minimize piping and condensate losses.

Our engineering expert

Still not sure about how to proceed?

YOU CAN WRITE TO ME AT inquiry@ny-engineers.com

Boilers play an essential role when it comes to the heating needs of buildings, particularly large buildings with varied heating loads. But they tend to consume very large quantities of fuel and account for a significant percentage of building emissions.

In the past decade increasingly stringent regulations relating to air emissions and other environmental issues, coupled with cost restraints, have led to a concerted effort by professional mechanical, electrical, and plumbing (MEP) engineers to improve the efficiency of boiler plants and to promote the use of energy-efficient boilers.

While there are various motivating factors for boiler replacement, a good rule of thumb is to replace any boiler if it is more than 15 years old. The fact is that if boilers are any older than this, the likelihood is that they will be operating at no more than 70% efficiency, often not more than 50%. This is because older models were considerably less efficient than contemporary devices, coupled with the fact that they inevitably suffer from wear and tear. Additionally, older boilers tend to be unreliable, and if they are faulty they might be dangerous.

New boilers not only operate more efficiently because they are new, but they are also designed for increased efficiency and safety. While boiler replacement will involve an initial investment, from day one it will save you money in operating costs.

Remember, too, that while old boilers and boiler systems may be replaced, others may be upgraded to improve energy efficiency.

There are different types of boilers and boiler plants that produce energy with different fuels.

Experienced MEP engineers at Nearby Engineers New York Engineers offer radiant heating design options that meet all the relevant building codes and standards and enable building owners and managers to:

- Decrease heating costs

- Reduce the environmental impact of boiler plants

In very basic terms, hot water boilers are designed to heat indoor spaces and to generate hot water. Steam boilers are more commonly used in industry for anything from food processing to metal smelting.

In commercial and residential buildings, traditional boilers provide steam via pipes to steam radiators or hot water via radiant floor systems or baseboard radiators. Today, the hot water generated in boilers is usually distributed through pipework. Where heating systems still utilize steam, these can be redesigned or reconfigured to use hot water. Alternatively, the entire system can be replaced with a more cost-efficient, environmentally friendly arrangement.

Although electric boilers are designed for high efficiency and are sometimes used in smaller commercial buildings or for domestic use, they are costly to operate, particularly in large buildings. For this reason, if electric heating is required, we recommend the installation of a heat pump system rather than boilers.

More commonly, when installed for commercial or industrial use, boilers mostly burn fossil fuels to generate heat.

- Natural gas is commonly used for boilers and it is currently the preferred fuel. Provided by utility services, it is a reliable fuel source that releases considerably less CO2 into the environment than coal or oil.

- Heating oil, which may be stored in a tank in your basement or garage, or even buried in the ground, can be an efficient fuel for boilers. The boiler should though be a condensing rather than an old-fashioned non-condensing type because it is considerably more energy-efficient.

- Liquid propane (LP) gas, which is also stored in a tank on the property, can be cost-effective if available for scheduled deliveries. In the interests of decarbonization, millions of Americans are switching from LP gas to natural gas as a fuel choice. This is something that can be done when boilers are replaced.

- Biomass, which is a renewable fuel that is composed mostly of carbon dioxide, can be a viable option, but only where large volumes of organic matter are available for use. However, it currently only accounts for about 2% of the fuel used for boilers.

Coal is mostly used in steam turbines to fire power plants.

Generally, products that meet Federal Energy Management Program (FEMP) efficiency requirements and/or those that qualify in terms of ENERGY STAR standards have an input rating of no more than 300,000 Btu/h (which is the measure of British thermal units – the amount of heat energy it takes to raise the temperature of a pound of water by 1 deg. F – in an hour) are acceptable for residential use. Commercial and industrial boilers have input ratings that are higher than this and are excluded from these consumer-orientated guidelines for obvious reasons. Instead, a mechanical, electrical, and plumbing (MEP) engineer will have the knowledge and expertise to make the choice.

Nevertheless, it’s useful to understand the way efficiency ratings of boilers work. The U.S. Environmental Protection Agency (EPA) provides efficiency levels that relate to products and their specifications on its ENERGY STAR website. Federal buyers also use ENERGY STAR data to identify and verify compliant models.

What is important is that the efficiency of boilers is measured by annual fuel utilization efficiency (AFUE). This reveals how efficiently appliances convert the energy from the fuel used to power them over a period of a year. So, for example, if a boiler has an AFUE of 90% (which is considered to be highly efficient), that is the percentage of fuel that is converted into heat while 10% is lost, usually up chimneys that may or may not be ducted.

While heat can be lost in the piping that is incorporated in boiler plants and systems, these heat losses are not included in the AFUE, even though they can be substantial. This is why it is so important for pipework to be designed to maximize efficiency.

The Federal Trade Commission (FTC) requires the AFUE percentage to be displayed on all boilers so that engineers and consumers know what they are buying and can compare the heating efficiencies of different models.

The U.S. Department of Energy (DOE) compares the efficiency of different heating systems:

- Old systems are not energy efficient and their AFUE rating is between 56% and 70%. Generally heavy heat exchangers, old boilers incorporate a continuous pilot light and a natural draft that results in a constant flow of combustion gases.

- Mid-efficiency systems have an AFUE of around 80% to 83% largely because they are smaller in size and lighter in weight, which reduces cycling losses. The flue pipe also has a much smaller diameter and there is no pilot light, instead, ignition is electronic. Exhaust fans in mid-efficiency heating systems control the flow of combustion gases and air more accurately.

- A 90% to 98.5% AFUE indicates that the heating system is highly efficient. This rating usually applies to new designs that feature sealed combustion and a secondary heat exchanger where flue gases are condensed to maximize energy efficiency.

Additionally, the DOE recommends that sealed-combustion units are specified because they avoid the risk of gases back-drafting and escaping into the inside airof buildings, big or small. Boilers that are not sealed-combustion units are also known to waste energy because they tend to draw the heated air into the unit and this air escapes up the chimney.

The DOE recommends ENERGY STAR natural gas boilers that have an AFUE of 90%, or better still, the best available gas boilers that have an AFUE of 97% which have a lifetime cost saving of nearly double the ENERGY STAR models.

However, the DOE also advises in general terms that “efficient products” are only cost-effective when the energy savings of the boiler during its entire lifetime are greater than the up-front costs when compared to the same equation of an option that is less efficient.

While it is safe to assume that ENERGY STAR-qualified products and those that meet FEMP requirements are cost-effective for their lifecycle, Nearby Engineers New York Engineers negates the need for guesswork and rule-of-thumb assessments. Instead, we will analyze every client’s needs and ascertain in individual situations what the best options are in terms of efficiency and cost.

For example, while it makes perfect sense to invest in high-efficiency boilers if you live in a cold climate area, where there are milder climatic conditions, the additional investment may not be justifiable.

Whether you have one boiler in your home or an elaborate boiler system in your building, if it is old, worn out, inefficient, or undersized, replacing it will save you money in the long term and ensure the system operates more efficiently.

Upgrading old boilers and related equipment can potentially halve not only fuel bills but also harmful emissions that pollute the air in buildings. The simplest solution is to replace old equipment, but it is important that they are correctly sized.

If the chimney or vent pipe is to be retained, it is vital that it is carefully checked when boilers are to be replaced. The liners of older chimneys often deteriorate, if indeed they were lined in the first place. If the building dates back to the late 1980s or early 1990s, non-condensing boilers might have been installed with plastic vent pipes prior to the advent of acceptable PVC pipes. If the plastic isn’t PVC, it must be removed and ideally replaced with a safe stainless steel vent pipe.

Having said that sealed-combustion units are much more efficient, they do tend to produce acidic exhaust gases that old, unlined chimneys cannot cope with. For this reason, the chimney or a new duct will need to be properly lined to accommodate the vented exhaust gases.

It may be preferable to install new equipment that doesn’t require venting via a chimney.

The physical integrity of heat exchangers will also need to be checked. If these leak, there is a real danger that harmful combustion gases will mix with the air inside the building. If the whole system is to be replaced or retrofitted, a technician should be employed to carry out a combustion-efficiency test.

Many different factors need to be considered when selecting a replacement boiler. The challenge is that while it may seem logical to replace it with something similar but better, this is not necessarily the most sensible approach.

For instance, we’ve discussed the different fuel options and said that natural gas is the best option. So if you are currently using a boiler that operates with LP gas or oil, and natural gas is available from your local utility, then it will likely be a better option to switch.

The other factor to consider is whether the existing boiler system runs on hot water or steam. Heating systems that run on steam tend to be older and so you may want to upgrade the system in its entirety.

We discussed vents and chimneys above, and these elements will need to be carefully considered when a replacement boiler is chosen.

Whichever boiler is chosen to replace an old or faulty one, it is essential that it meets boiler standards including those established by the American Society of Mechanical Engineers (ASME).

It is advisable to consult a professional home heating contractor or an MEP engineering firm before you go ahead with any boiler replacement operations.

Nearby Engineers New York Engineers is headquartered in New York City but has an office in Chicago and a satellite office in India. Our MEP engineers are available to work with clients in many other areas. Call us today to discuss your needs, or drop us an email.

Boiler Replacement

Boilers play an essential role when it comes to the heating needs of buildings, particularly large buildings with varied heating loads. But they tend to consume very large quantities of fuel and account for a significant percentage of building emissions.

In the past decade increasingly stringent regulations relating to air emissions and other environmental issues, coupled with cost restraints, have led to a concerted effort by professional mechanical, electrical, and plumbing (MEP) engineers to improve the efficiency of boiler plants and to promote the use of energy-efficient boilers.

when you should replace your old boiler?

While there are various motivating factors for boiler replacement, a good rule of thumb is to replace any boiler if it is more than 15 years old. The fact is that if boilers are any older than this, the likelihood is that they will be operating at no more than 70% efficiency, often not more than 50%. This is because older models were considerably less efficient than contemporary devices, coupled with the fact that they inevitably suffer from wear and tear. Additionally, older boilers tend to be unreliable, and if they are faulty they might be dangerous.

New boilers not only operate more efficiently because they are new, but they are also designed for increased efficiency and safety. While boiler replacement will involve an initial investment, from day one it will save you money in operating costs.

Remember, too, that while old boilers and boiler systems may be replaced, others may be upgraded to improve energy efficiency.

Classification of Boilers

There are different types of boilers and boiler plants that produce energy with different fuels.

Experienced MEP engineers at Nearby Engineers New York Engineers offer radiant heating design options that meet all the relevant building codes and standards and enable building owners and managers to:

- Decrease heating costs

- Reduce the environmental impact of boiler plants

In very basic terms, hot water boilers are designed to heat indoor spaces and to generate hot water. Steam boilers are more commonly used in industry for anything from food processing to metal smelting.

In commercial and residential buildings, traditional boilers provide steam via pipes to steam radiators or hot water via radiant floor systems or baseboard radiators. Today, the hot water generated in boilers is usually distributed through pipework. Where heating systems still utilize steam, these can be redesigned or reconfigured to use hot water. Alternatively, the entire system can be replaced with a more cost-efficient, environmentally friendly arrangement.

Although electric boilers are designed for high efficiency and are sometimes used in smaller commercial buildings or for domestic use, they are costly to operate, particularly in large buildings. For this reason, if electric heating is required, we recommend the installation of a heat pump system rather than boilers.

More commonly, when installed for commercial or industrial use, boilers mostly burn fossil fuels to generate heat.

- Natural gas is commonly used for boilers and it is currently the preferred fuel. Provided by utility services, it is a reliable fuel source that releases considerably less CO2 into the environment than coal or oil.

- Heating oil, which may be stored in a tank in your basement or garage, or even buried in the ground, can be an efficient fuel for boilers. The boiler should though be a condensing rather than an old-fashioned non-condensing type because it is considerably more energy-efficient.

- Liquid propane (LP) gas, which is also stored in a tank on the property, can be cost-effective if available for scheduled deliveries. In the interests of decarbonization, millions of Americans are switching from LP gas to natural gas as a fuel choice. This is something that can be done when boilers are replaced.

- Biomass, which is a renewable fuel that is composed mostly of carbon dioxide, can be a viable option, but only where large volumes of organic matter are available for use. However, it currently only accounts for about 2% of the fuel used for boilers.

Coal is mostly used in steam turbines to fire power plants.

Efficiency Rating of Boilers

Generally, products that meet Federal Energy Management Program (FEMP) efficiency requirements and/or those that qualify in terms of ENERGY STAR standards have an input rating of no more than 300,000 Btu/h (which is the measure of British thermal units – the amount of heat energy it takes to raise the temperature of a pound of water by 1 deg. F – in an hour) are acceptable for residential use. Commercial and industrial boilers have input ratings that are higher than this and are excluded from these consumer-orientated guidelines for obvious reasons. Instead, a mechanical, electrical, and plumbing (MEP) engineer will have the knowledge and expertise to make the choice.

Nevertheless, it’s useful to understand the way efficiency ratings of boilers work. The U.S. Environmental Protection Agency (EPA) provides efficiency levels that relate to products and their specifications on its ENERGY STAR website. Federal buyers also use ENERGY STAR data to identify and verify compliant models.

What is important is that the efficiency of boilers is measured by annual fuel utilization efficiency (AFUE). This reveals how efficiently appliances convert the energy from the fuel used to power them over a period of a year. So, for example, if a boiler has an AFUE of 90% (which is considered to be highly efficient), that is the percentage of fuel that is converted into heat while 10% is lost, usually up chimneys that may or may not be ducted.

While heat can be lost in the piping that is incorporated in boiler plants and systems, these heat losses are not included in the AFUE, even though they can be substantial. This is why it is so important for pipework to be designed to maximize efficiency.

The Federal Trade Commission (FTC) requires the AFUE percentage to be displayed on all boilers so that engineers and consumers know what they are buying and can compare the heating efficiencies of different models.

The U.S. Department of Energy (DOE) compares the efficiency of different heating systems:

- Old systems are not energy efficient and their AFUE rating is between 56% and 70%. Generally heavy heat exchangers, old boilers incorporate a continuous pilot light and a natural draft that results in a constant flow of combustion gases.

- Mid-efficiency systems have an AFUE of around 80% to 83% largely because they are smaller in size and lighter in weight, which reduces cycling losses. The flue pipe also has a much smaller diameter and there is no pilot light, instead, ignition is electronic. Exhaust fans in mid-efficiency heating systems control the flow of combustion gases and air more accurately.

- A 90% to 98.5% AFUE indicates that the heating system is highly efficient. This rating usually applies to new designs that feature sealed combustion and a secondary heat exchanger where flue gases are condensed to maximize energy efficiency.

Additionally, the DOE recommends that sealed-combustion units are specified because they avoid the risk of gases back-drafting and escaping into the inside airof buildings, big or small. Boilers that are not sealed-combustion units are also known to waste energy because they tend to draw the heated air into the unit and this air escapes up the chimney.

The DOE recommends ENERGY STAR natural gas boilers that have an AFUE of 90%, or better still, the best available gas boilers that have an AFUE of 97% which have a lifetime cost saving of nearly double the ENERGY STAR models.

However, the DOE also advises in general terms that “efficient products” are only cost-effective when the energy savings of the boiler during its entire lifetime are greater than the up-front costs when compared to the same equation of an option that is less efficient.

While it is safe to assume that ENERGY STAR-qualified products and those that meet FEMP requirements are cost-effective for their lifecycle, Nearby Engineers New York Engineers negates the need for guesswork and rule-of-thumb assessments. Instead, we will analyze every client’s needs and ascertain in individual situations what the best options are in terms of efficiency and cost.

For example, while it makes perfect sense to invest in high-efficiency boilers if you live in a cold climate area, where there are milder climatic conditions, the additional investment may not be justifiable.

Replacing & Maintaining Boiler Systems

Whether you have one boiler in your home or an elaborate boiler system in your building, if it is old, worn out, inefficient, or undersized, replacing it will save you money in the long term and ensure the system operates more efficiently.

Upgrading old boilers and related equipment can potentially halve not only fuel bills but also harmful emissions that pollute the air in buildings. The simplest solution is to replace old equipment, but it is important that they are correctly sized.

If the chimney or vent pipe is to be retained, it is vital that it is carefully checked when boilers are to be replaced. The liners of older chimneys often deteriorate, if indeed they were lined in the first place. If the building dates back to the late 1980s or early 1990s, non-condensing boilers might have been installed with plastic vent pipes prior to the advent of acceptable PVC pipes. If the plastic isn’t PVC, it must be removed and ideally replaced with a safe stainless steel vent pipe.

Having said that sealed-combustion units are much more efficient, they do tend to produce acidic exhaust gases that old, unlined chimneys cannot cope with. For this reason, the chimney or a new duct will need to be properly lined to accommodate the vented exhaust gases.

It may be preferable to install new equipment that doesn’t require venting via a chimney.

The physical integrity of heat exchangers will also need to be checked. If these leak, there is a real danger that harmful combustion gases will mix with the air inside the building. If the whole system is to be replaced or retrofitted, a technician should be employed to carry out a combustion-efficiency test.

Choosing the Best Replacement Boiler

Many different factors need to be considered when selecting a replacement boiler. The challenge is that while it may seem logical to replace it with something similar but better, this is not necessarily the most sensible approach.

For instance, we’ve discussed the different fuel options and said that natural gas is the best option. So if you are currently using a boiler that operates with LP gas or oil, and natural gas is available from your local utility, then it will likely be a better option to switch.

The other factor to consider is whether the existing boiler system runs on hot water or steam. Heating systems that run on steam tend to be older and so you may want to upgrade the system in its entirety.

We discussed vents and chimneys above, and these elements will need to be carefully considered when a replacement boiler is chosen.

Whichever boiler is chosen to replace an old or faulty one, it is essential that it meets boiler standards including those established by the American Society of Mechanical Engineers (ASME).

It is advisable to consult a professional home heating contractor or an MEP engineering firm before you go ahead with any boiler replacement operations.

Nearby Engineers New York Engineers is headquartered in New York City but has an office in Chicago and a satellite office in India. Our MEP engineers are available to work with clients in many other areas. Call us today to discuss your needs, or drop us an email.