Ultra Premium Efficiency Motors: The IE5 Efficiency Class

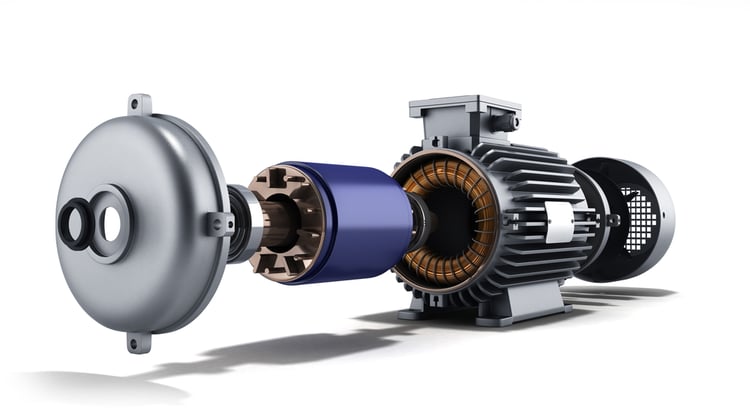

Electric motors have many applications in residential, commercial and industrial buildings. Due to their widespread use, motors represent over 45% of global electricity consumption. Industry associations like NEMA and IEC are aware of this, and they are constantly working on standards to improve motor efficiency.

- Higher efficiency motors can save building owners thousands of dollars each year.

- With widespread use, efficient motors could also lower operating costs for power companies, by decreasing the transmission and distribution load on the grid.

- Efficient motors also offer an environmental benefit, since a large portion of the electricity supply still comes from fossil fuels.

NEMA has three motor efficiency classes: Standard, Energy Efficient and Premium Efficiency. On the other hand, IEC has four classes: IE1, IE2, IE3 and IE4. The first three IEC classes are roughly equivalent to the NEMA classes, while the IE4 class is referred to as Super Premium Efficiency. These efficiency classes are specified in the IEC 60034-30-1 standard, and the latest version was published in 2014.

Find the best ways to save electricity with a professional energy audit.

The next version of the IEC standard will introduce the IE5 class, known as Ultra Premium Efficiency. Energy losses are reduced by 20% or more between classes, which means an IE5 motor will have a 20% loss reduction with respect to an IE4 motor. The Ultra Premium Efficiency class has not been specified in standards yet, but some manufacturers have already developed motors that will be compliant.

Estimating the Savings from a Motor Upgrade

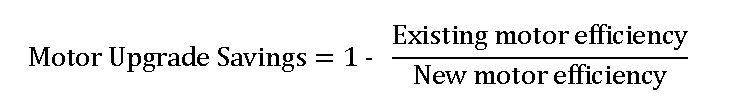

To get an accurate calculation of how much you can save with an electric motor upgrade, an energy audit is the best option. However, the percentage savings can be estimated with the following formula:

Assume a motor with 85% efficiency is replaced with a unit that has 91% efficiency. Using the formula above, the savings value is 0.066 or 6.6%. If the existing motor was consuming 300,000 kWh per year, the new one will save 19,800 kWh. Considering an electricity price of 16 cents/kWh, this is equivalent to $3,168 in annual savings.

The dollar savings achieved with a motor upgrade are determined by three main factors:

- The efficiency difference between the existing motor and the upgrade.

- The operating schedule of the motor.

- The local electricity tariff.

To maximize the return on investment from a motor upgrade, the best approach is starting with motors that have a low efficiency and a long operating schedule.

Increasing the Savings from a Motor Upgrade with Speed Control

When motors are used intermittently or at part-load during extended periods, speed controls can achieve additional savings. Variable frequency drives (VFD) reduce the input voltage and frequency provided to a motor, lowering the RPM and power consumption. This control method is especially effective for fans and pumps, which tend to have a variable workload throughout the day.

- Considerable savings are possible if motors are upgraded to IE5 Ultra Premium Efficiency, and then equipped with VFDs.

- In the case of HVAC systems, a motor upgrade can achieve synergy with other measures such as chiller and boiler replacements.

When upgrading motors, a careful inspection of the wiring and electrical protections is strongly recommended. Motor upgrades are generally expensive projects, and protecting that investment is in the best interest of building owners. The power supply quality is also important to ensure that motors have a long service life, since they are vulnerable to issues like under-voltage and phase voltage imbalance. Electrical engineers can find issues that are affecting your installation, to then propose cost-effective solutions.

Meet building codes and save on water bills with a professional plumbing design. Nearby EngineersNew York Engineers has an 80% first-time design approval rate - write at info@ny-engineers.com or dial (786) 788-0295212-575-5300.

Michael Tobias

Michael Tobias, the Founding Principal of NY Engineers, currently leads a team of 150+ MEP/FP engineers and has led over 4,000 projects in the US

Join 15,000+ Fellow Architects and Contractors

Get expert engineering tips straight to your inbox. Subscribe to the NY Engineers Blog below.