Electrical Installations: Pull Box Sizing

Pull boxes are used along with conduit to simplify wiring installation, hence their name. They are made of sheet metal, cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation. Pull boxes allow long wiring runs to be installed in shorter intervals, and can be used for both straight and angled pulls.

Although they have the same appearance as junction boxes, pull boxes do not have wiring connections inside. They are only access points for pulling and feeding conductors into a raceway system. Their use is mandatory in conduit runs where the number of bends between outlets exceeds the maximum number permitted by the NEC (National Electric Code).

Pull box sizing is based on the size and number of conductors, as well as the number of raceways and their diameter. For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.

Straight Pulls

In straight pulls, conduit enters and leaves on opposite sides of the box. The depth of a box for a straight pull is determined by the size of the largest conduit and by space required by locknuts and bushings. On the other hand, the pull box length must be at least eight times the diameter of the largest conduit:

- Assume a pull box has four conduit runs, and the largest diameter is 4”

- Minimum box length = 8 x 4” = 32”

Angle Pulls, U-Pulls and Splices

Boxes and conduit bodies containing conductors 4 AWG or larger, and containing angle or U-pulls must be sized in accordance with the specifications of NEC article 314.28(A)(2).

Angle Pulls

For angle pulls, the distance between each raceway entry inside the box and the opposite wall of the box must be the sum of the following:

- Six times the trade size of the largest raceway in a row.

- The sum of the diameters of all other raceway entries in the row.

Assume a pull box has a 90° turn with three raceways, with diameters 4”, 2” and 2”. The calculation procedure would be as follows:

- Six times the largest raceway diameter = 6 x 4” = 24”

- Sum of all other raceway diameters = 2” + 2” = 4”

- Total = 24” + 4” = 28”

In addition, the straight distance between the entry and exit points of each circuit must be six times the respective conduit diameter. In the example above, the required separations are:

- Separation for circuits in 4” conduit = 6 x 4” = 24”

- Separation for circuits in 2” conduit = 6 x 2” = 12”

Looking For Electrical Engineering Services?

U-Pulls

When conductors enter and leave from the same wall, the distance from where the raceways enter to the opposite wall is calculated with the same procedure used for angle turns:

- Six times the trade size of the largest raceway in a row.

- The sum of diameters for all other raceways on the same wall and row.

Note that the entry and exit points are counted separately for each conductor run. If a circuit uses 3” conduit and uses a pull box for a u-turn, the procedure is as follows:

- Six times the largest raceway diameter = 6 x 3” = 18”

- Sum of all other raceway diameters = 3”

- Total = 18” + 3” = 21”

The straight-line distance between the entry and exit point is just like in angle turns: six times the conduit diameter. In the example above, the required separation is 18” (6 x 3”).

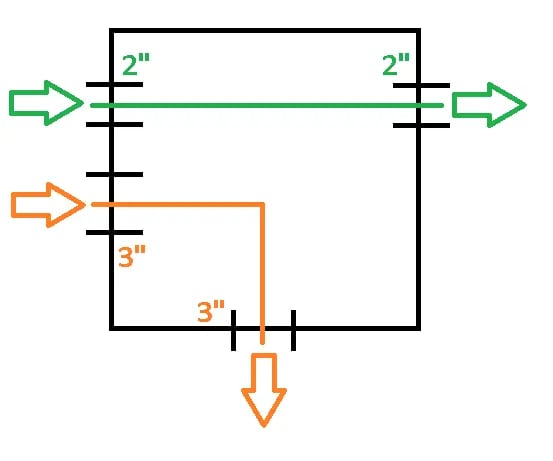

Combination Boxes with Straight and Angle Pulls

When there are straight and angle pulls in the same box, the calculations must be performed according to both sets of rules, and the largest resulting dimension applies. Assume the following combination pull:

- Straight pull with a 2” raceway

- Angled pull with a 3” raceway

Height Calculation

This calculation is straightforward because there is only one possibility: six times the largest raceway plus the sum of the rest. There is only one raceway, so it is multiplied by six and nothing else is added.

- Height = 6 x 3” = 18”

Width Calculation

In this case there are two possibilities, so both calculations are performed and the largest value is chosen. Option #1 is 8 times the diameter for the straight pull, and Option #2 is 6 times the largest raceway plus all other diameters.

- Width (Option 1) = 8 x 2” = 16”

- Width (Option 2) = 6 x 3” + 2” = 18” + 2” = 20”

Pull Box Dimensions

This pull box must have a height of 18” and a width of 20”. For the angle pull, the distance between the entry and exit is 18” (six times the conduit dimension, which is 3”).

Importance of the Design Procedure

While pull boxes are convenient, keep in mind that they require materials and labor, and can increase project cost if used excessively. The best recommendation is to hire a qualified design firm to optimize the electrical layout, ensuring that pull boxes are only used where necessary.

Energy efficiency also helps optimize electrical installation costs. A lower load requires smaller wiring, which in turn uses smaller a smaller conduit diameter and accessories. The price difference may not be much for a single circuit, but quickly adds up in a large project such as a high-rise building.

Editors Note: This post was originally published in November 2017 and has been revamped and updated for accuracy and comprehensiveness.

An electrical design makes your building safer, while reducing your power bills. NY Engineers has completed over 1000 projects, and you can email at info@ny-engineers.com or call (786) 788-0295212-575-5300.

FAQs

A pull box, or junction box in some cases, is a protective enclosure in conduit runs that eases pulling conductors over long distances or bends. It reduces friction, prevents damage, and provides access for maintenance and modifications.

The NEC, specifically Article 314, governs pull box sizing, covering boxes, conduit bodies, handhole enclosures, and pull boxes. Always check local codes and project specifications, as they may be stricter than the NEC.

Electrical pull boxes are necessary for several reasons:

- Long Conduit Runs: Excessive friction can make wire pulling difficult or impossible in long conduit runs. Pull boxes break up these runs into manageable sections.

- Multiple Bends: Each bend in a conduit run increases friction. Pull boxes after bends reduce pulling stress.

- Complex Routes: Where conduit routes are complex or change direction frequently, pull boxes simplify the installation process.

- Conductor Splicing: Some pull boxes, properly sized, can be used to splice conductors. This is a cost-effective way to make changes in the conductor routing.

For angle or U pulls, the NEC (Article 314.28 [A)(2)) requires the distance between each raceway entry point and the opposite wall of the pull box to be at least six times the trade diameter of the largest raceway entering the wall. This applies to each raceway individually. The distance between raceway entries within the same wall must also be considered.

Formula: Minimum Distance = 6 x (Largest Raceway Trade Diameter) for each raceway. Also, the sum of the diameters of all raceways entering one side of the box, plus the distance needed for locknuts or bushings, must be considered.

The choice of pull box material depends on the application, environment, and local codes. Metallic pull boxes offer durability and grounding capabilities, while non-metallic ones, like PVC or fiberglass, resist corrosion in wet conditions.

Ankit Javeri

Ankit is the Project Manager at NY Engineers, who holds an M.Tech. Some of his projects includes Community Access, Jackson Avenue

Join 15,000+ Fellow Architects and Contractors

Get expert engineering tips straight to your inbox. Subscribe to the NY Engineers Blog below.