Fabrication Building Design

Conform to quality industry standards when you subject all your fabrication building design for professional check, review and approval.

Eliminate discrepancies and align fabrication sheets with bill of materials for your cost optimization.

Switch from traditional method to BIM-ready approach by coordinating design and fabrication in a simultaneous timeline for efficiency.

We can all agree that fabrication, per se, is a complex process of supplying, manufacturing, assembling and installing components together. To deal with such complexity, fabrication sheets in itself have different types to compensate for all the details needed to be captured.

Here are the typical drawings that our engineers advise you to look out for in fabrication sheets:

From a micro scale, single part drawing encompasses all specific information needed for the fabrication of your components. This includes cutting list, dimension tolerances, weight, material specification, linear and angular dimensions, hole dimensions, sections and more. Be aware, however, that you should not show more than what is required so as to eliminate confusion.

Taking reference from the name itself, assembly drawings show the fabricator or the welder illustrations on how to link and assemble all the parts together. On such notice, this can also include finishes, engineering bill of materials (EBOM) and manufacturing bill of materials (MBOM).

Moving onto the macro scale, we have general arrangement drawing as another type of fabrication sheet. You can rely on this drawing to serve as your master plan in adjoining all the component parts together. In a way, this general arrangement drawing combines the single part and assembly drawing together.

Fabrication sheets are often treated as an afterthought, but that shouldn’t be the case. When all project stakeholders are still in the design phase, most are preoccupied with finalizing the concepts so the building project can move towards the construction phase. This traditional process can consume so much time, especially when design iterations from the client back to the consultants are endless.

For fast-track constructions needing agile solutions, we can’t afford to bank on fabrication sheets as an afterthought, especially when all project constraints are imposed on the client or building homeowner.

Here’s how detailed fabrication sheets act as your game changer in the AEC industry:

Fabrication sheets, without a doubt, show you how to bring your building components to life. If there’s one detail that’s missing, chain reactions can go so far as hampering the productivity of your fabrication line, or worse, can take a toll on the project life cycle itself.

At Nearby Engineers New York Engineers , this is clearly one of the pitfalls that we proactively avoid. If you, as the client, ask us to generate your fabrication sheets, our keen eye will meticulously illustrate every detail needed for the building component’s constructability. Otherwise, if you hire a third-party fabricator to create the drawings, all these fabrication sheets will be subject for our rigorous check and approval to ascertain that all specific details are transparent.

This item should be non-negotiable, as any evidence that the fabrication drawings did not meet the industry standards can automatically equate to subpar value. Each discipline caters to their own industry standards and codes, and as specialized engineers looking out for our clients, here’s our professional advice: never compromise the function, structural integrity and quality of your fabricated components as this can be hazardous and costly for you in the long run.

The last thing any client or fabricator would want during its building project’s implementation is to jeopardize the safety of the workers. Not only will accountability cost so much on a legal perspective, good reputation is on the line and credibility of the organization can also be compromised. In turn, this could possibly affect the demand and supply of the labor for your fabrication, which can be very taxing especially when you are under pressure to chase your building project’s deadline.

In fact, at Nearby Engineers New York Engineers , we work hand-in-hand with the third-party fabricator while the design process is still underway. This gives us more lead time, decreased costs and overall, a safe working environment for your construction workers, fabricators and quality control officers.

In the previous section, our specialized engineers have settled the score on why great fabrication sheets are a must for every building project. On the opposite side of the spectrum, we also show you the learning curve and the possibilities when inaccuracy takes over the fabrication sheets:

As engineers thoroughly checking for the efficiency and errors of your fabrication sheets, we all know that the strict quality assurance in itself can be very time-consuming. If the review process coincides with the start date of construction and the fabrication drawings were still not reviewed by quality analysts and approved by consultants, then construction managers have no choice but to work with the resources they have on-site. In effect, this could lead to material wastage should the consultants issue change orders, long-lead items moved down the project timeline, and building components which are not fabricated on time.

Any missing parts on the fabrication sheets can lead to building components which are built incomplete, or not at all. When fabrication sheets show lack even one detail such as the dimensional tolerance needed, this can create a ripple effect for the fabrication line. Imagine the cause of delays when a single detail is missing: quantity take-offs are incorrect, rush purchase orders, inventory management and material supply for fabrication is insufficient, and lastly, building components are not fabricated just in time for the systems installation in your building facility.

In every aspect of the building project, experience and expertise are your criteria in leveraging the success of your facility. From architects to contractors, this also includes your nominated third-party fabricators and their own component detailers. Novices who do not have an experience can’t possibly comprehend the complexity needed to illustrate all the data needed in a fabrication sheet.

At NY Engineers, we are industry veterans who can walk our talk in creating precise and effective fabrication sheets.

From behind-the-scenes, here are the key factors that can make or break the production of your fabrication sheets:

On quality criteria for a third-party fabricator, we need to evaluate the capabilities on an apple-to-apple comparison of commercial and technical leverage. This means that your third-party fabricator should have a strong portfolio to back up its claim, and should be able to meet your project demands on time, at an excellent quality, for less costs. In other words, you need to look for experience and expertise for your building project’s success.

All building components have a zero starting point, and design is the catalyst for every phase in the project life cycle to begin with. This means that there’s a direct proportional relationship between design to manufacturing. For demanding large-scale and mixed-use complex projects, the scheduled turnover can put a pressure on all project stakeholders. And as such, all strategies implemented are designed for efficiency to meet the project timeline.

Case in point, however, there’s a drawback with “efficiency”. By definition, this combines fast and quality results. But in any case that your building project settles with inferior quality standards only to meet the project schedule, then this effectively negates the whole meaning of efficiency. Circumvention may take place – creating shortcuts which can be otherwise be disastrous for your building project.

This is why, from design down to manufacturing, quality control is a must. From space allocation, to construction documents, and finally to fabrication sheets, quality control should be on your top priority every step of the way. For building projects where design considerations and factors sprout from anywhere, it pays to be proactive than to be reckless only just for a few money savings.

And by the time your fabrication sheets hit the production line, you can rest easy knowing that your building components can be built in no time at all, since your drawings were subjected to the strictest quality control that can be implemented by our engineering consultants and quality analysts. At Nearby Engineers New York Engineers , we combine fast with quality results.

Both fabrication sheets and bill of materials are interrelated together. This means that any update on your fabrication sheets, can mean changes for your bill of materials.

Such is the case between an engineering bill of materials (EBOM) and manufacturing bill of materials (MBOM). MBOM is largely dependent on EBOM for its product design, and any design changes can directly affect all the parts list needed for MBOM. Same goes for fabrication sheets.

When fabrication sheets are not yet approved, and bill of materials is already in order for procurement, there could be possible complications down the line with change orders.

As MEP engineers who have worked extensively on all kinds of building projects from design to manufacturing, here are three items that you should key in:

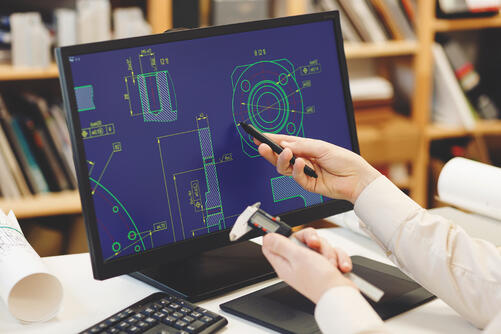

Technology evolves rapidly, and all for the right reasons. Specifically in fabrication, there’s a great divide between the traditional and modern workflow: BIM. All aspects from project stakeholders are integrated in a 3D-based building information model, as opposed to a flattened 2D design document given to a fabricator by the consultant after only the design phase.

This brings us to the critical issue of how linear process equates to inefficiency in the streamlined design-fabrication-construction process. In a traditional workflow, consultants are given ample time to review the project in a 3D-based setting, while the fabricators work from a flat 2D format handed off from consultants. And when the project calls for agile construction, the fabricators do not have sufficient time to illustrate and execute all the details due to lack of competitive visual aids and a shortened deadline.

On the other hand, BIM replaces this outdated traditional workflow with an efficient, modernized one. From linear to parallel process, a BIM-based workflow enables the consultants to bring in the fabricators early in the design phase to provide all the fabrication details. In turn, this paradigm shift can be beneficial for you wherever you are in the building project spectrum as this mandates time and cost savings, compounded with quality details for the fabrication sheets.

Realize all the maximum returns on investment that you can recoup when you work with Nearby Engineers New York Engineers for your fabrication sheets. On top of being an expert engineering design partner, you can bank on our two-way functionality to implement quality control on your drawings: impose strict quality control on the approval of your fabrication sheets when working from the consultant’s end, or create precise drawings from being a streamlined designer and fabricator all at once.

Whatever the structure is, Nearby Engineers New York Engineers exceed efficiency in all forms. Browse through our diverse list of projects and learn how we can help you build your components to reality with our comprehensive fabrication sheets.