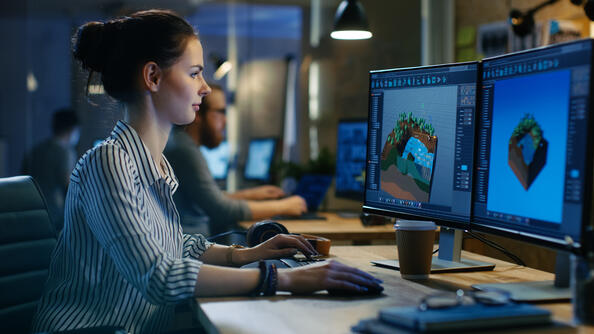

3D Modelling

Utilize 3D modelling as an innovative precursor for advanced technologies in design, construction, and operations.

Increase client buy-ins and improve stakeholder relationship by communicating your design intent clearly and effectively.

Bridge the gap from design to handover through 3D modelling, so you can achieve more in less time.

Technology is evolving fast, and all for the right reasons. Waves of big impact is currently hitting the architecture, engineering and construction (AEC) industry, as BIM proves to be a game-changer on its own merits. Industry players who are keen on innovation ride the coattails of BIM’s success, but surely, the transition has not been smooth-sailing for a decade as conformists still cling to their traditional 2D methods amidst the wide adoption of BIM in a global scale.

Truthfully, scale can be a very big factor that could hamper the fast implementation of BIM in the AEC industry. Linear 2D partisans, such as small-scale local architectural firms and general contractors who are not effectively reaping BIM’s benefits, are slowly half-baked in their own workflow: part 2D CAD, and part 3D BIM. We can see how 2D CAD still benefits the small-scale users of the AEC industry, especially when outputs call for precise drawing line work.

But for MEP engineers like us, and other industry specialists such as construction managers and world-class architectural firms who work on large-scale complex projects of all building types, switching from 2D drafting to 3D modelling has been our solution, which in turn, effectively brought us more solutions.

Multidisciplinary fields working on such complex building projects need to find a common ground in efficiency, productivity and decision-making. This is in the form of BIM: an intelligent 3D-modelling based informational process connecting all specialists in a multi-collaborative environment from planning, design, construction, manufacturing, operation and facilities management phases.

At Nearby EngineersNew York Engineers, we want to bring this engineering solution to you.

3D modelling has been around for quite some time in the industry, but the technology has not been utilized effectively especially when it competes with its own 2D AutoCAD counterpart. However, BIM says otherwise. For the process to be fully brought to life, it needs to have a 3D-modelling based software which could cater efficiently to all industry players on all phases of the building project life cycle. So far, there has been a positive reception and this clearly explains what drives the unexplainable growth of 3D modelling in the AEC industry.

Here’s what you could take away on 3D modelling, from some of the notable industry experts in AEC:

It’s not uncommon to see that architects are always in a state of iterative process, as client demands can change from schematic down to design development phases. Even in extreme cases where construction commences, clients can change their decision last-minute on a certain aspect, zone or space of the building project – causing a ripple effect on the critical path item of your building project.

3D modelling delivers such solution for these last-minute iterations, as visualizations can early on provide a clear client-architect communication – purging all the language barriers from the technical jargons in the form of a visual aid. Even for prospective building owners, 3D modelling seals the deal on client-buy in with the help of marketing visualizations.

When compared from architecture: engineering is a different discipline, with a different workflow. Engineers on all sub-disciplines from mechanical, electrical and plumbing might have specific variable components to work on, but all can attest to how 3D modelling serves as a better baseline tool for understanding the interconnectivity of building systems. As MEP engineers working on local to global scale with your building projects, 3D modelling has proven to be a time-saving and cost-effective asset.

On a manufacturing perspective, 3D modelling has proven time and time again to be a key factor in the efficient delivery of prefabricated components in MEP, architectural and structural disciplines. As modular construction scales up for growth in the AEC industry, manufacturers have to keep up with speed and quality. Through 3D modelling, architects, engineers, and manufacturers can all work hand-in-hand to produce the parametric components of your building structure.

Extending design to fabrication has been a real challenge back when 2D workflow is at its optimal peak, but thanks to the advent of 3D modelling and all the competitive software packages, streamlining the process especially for long-lead MEP items is now an easy feat.

As you can see, technology plays a vital role in the AEC industry, albeit much of it has not been utilized previously due to these certain factors:

All these aspects certainly took a toll on the technological growth of the industry, but now that state-of-the-art advancements disrupt the industry as of late, there’s no reason why we should not take part in this revolution. 3D modelling is changing the way we think, and evidently, utilizing it early on in our workflow can certainly tip the scales in your favor. At Nearby EngineersNew York Engineers, we are evidently reaping the benefits from this innovation.

Long gone are the boxy building structures, curvy hyperboloid-shaped parametric structures are now the norm. That’s one powerful architectural and structural advantage you can get from a streamlined 3D-model based design-to-fabrication process.

In terms of engineering MEP components, manufacturing heavily relies on engineering for sufficient design data on fabrication. Case in point, the linear relationship between EBOM and MBOM. Any incomplete detail from the engineering design phase can directly affect your component assembly in manufacturing. This is where 3D modelling proves to be beneficial in our case as utilizing this can produce point-by-point details for your MEP components – effectively reducing rework and producing more components for your building structure in less time and costs.

From architects to general contractors involved in the building project lifecycle, all industry specialists are in agreement that architecture, engineering and construction (AEC) is currently on the precipice of innovation. To prove this point, 3D modelling continuously serves as the catalyst and bridge in developing technological advancements related to the building industry.

Confusion lies around the concepts of BIM and virtual design and construction (VDC) nowadays. For your information, both are considered as novel process in the AEC industry, but we need to draw the fine line between the two. BIM is an information-rich 3D-based modeling process allowing all project stakeholders to effectively communicate from conceptual to completion, and VDC is a process that involves managing the integrated multidisciplinary performance models.

Despite this thin line, this doesn’t negate the fact that all processes are centered around how 3D modelling is essential for both workflows. At Nearby EngineersNew York Engineers, we clearly identify the crucial position of 3D modeling in its precursor state for BIM and VDC.

All things considered in the three-dimensional world, here are only some of the few of the outstanding innovations our AEC industry currently revels in:

In today’s world where competition is fierce, and only the best come out on top, leveraging innovation is the key for everyone’s success. This digital age, our MEP engineers work with these present innovations to give you the best outcome on your building facilities.

At Nearby EngineersNew York Engineers, we do not only survive, but we thrive. We transform original ideas to sustainable solutions.

At Nearby EngineersNew York Engineers, our profound expertise in MEP engineering has continuously lent us the exposure to work in all types of building occupancies. With this experience comes the knowledge that building systems comprise of very complex details. Working with clients and building owners, we know better than to present them with consolidated 2D mechanical, electrical and plumbing drawings as this can definitely result in communication blunders. If, from our end, two-dimensional plans do not explicitly serve their purpose in clearly visualizing our plans on a global scale – what more for the first-time building owners who see through a layperson’s eyes?

It is through this dilemma that we see how 3D modelling benefits all end-users in the building and construction spectrum. For expert engineers like us who are primed for scrutinizing every detail in the engineering plans, we can’t emphasize enough how deficient 2D drafting is for our workflow. Perhaps for final detailing drafted with precise lines, 2D workflow methodology can serve its real purpose for our MEP engineers.

However, initial design phases require us to engineer the MEP components on a macro perspective, and 3D modelling delivers the solution to our conundrum. We need to work in a spatial environment and analyze your building systems in three-dimensional context, as this will help better understand how all three disciplines of mechanical, electrical and plumbing engineering can work together harmoniously for your building’s optimized performance.

With BIM integrated in 3D modelling, our specialized engineers can specify the material properties for your MEP components, analyze complex pressure and flow calculations, automate changes on multiple 2D and 3D views of your building project, and most notably, mitigate on-site field errors as conflict detection reduces clash interfaces.

To sum it up, here are the three-way benefits all end-users can gain with MEP 3D modelling:

Enter modern codes, building laws, design requirements, specifications, project timeline, zoning ordinances, site logistics, structural integrity, sustainability, multiple stakeholders, technology and all other aspects needed to be considered to build your structure to reality – design and construction proves to be one of the most time-consuming and intensive undertaking for all AEC professionals.

All contextual factors aside, the bottom line for the golden triangle of design and construction involves:

How does 3D modelling factor into this equation? Our proficient team of engineers show you the learning curve of how the three critical items work together for your building’s success.

Anytime you move the slider on the time constraint, this can react in a ripple effect or domino reaction with cost and quality constraints. Take for instance, delays in your construction schedule can result in higher material and labor costs, subpar quality standards, increased change orders, liquidated damages when contractor’s competence is in question, or accelerated claims from the contractor when the client holds the project then unnecessarily demands for a rushed timeline to meet the turnover deadline.

There’s no clear evidence of where the obstacle originated from, but in all such cases, we can draw conclusion that 3D modelling can efficiently negate these design and construction blunders.

Here are some advantages that you can get from 3D modelling:

When viewed from the cost-time-quality constraints respectively, 3D modelling decreases your overall development costs while reducing project timeline and implementing value-engineered items.

In a few words, Autodesk Revit offers you the best integrated solution for your 3D modelling projects in the AEC industry. From core basic functionalities to advanced digital integration, Revit delivers excellent results in an all-in-one software package.

Our expert engineers enumerate why you should choose Revit over any other 3D modelling software for your building projects:

Reserve quick wins for your organization and leverage your advantage with our expertise on 3D modelling. Experience the plethora of benefits you can get from expert engineering knowledge backed by digital-model-based workflow. Learn more of how Nearby EngineersNew York Engineers can give your building facility a competitive edge by scanning our list of top 3D modelling projects.