CFD Analysis

Time is money, and with CFD Analysis in place, you get more savings in less time with your data acquisition.

From chemical engineering to medical applications, almost all industries cater to CFD Analysis for optimization and performance of fluid dynamics.

Get a sneak peek on the performance of your fluid flow dynamics from conceptual design to turnover.

When it comes to wood and steel structure design, these two trusted materials behave predictably given their static properties and simplified formulas. Determining the set of equations to calculate the loads on your building structures is an easier feat. Consequently, meeting your cost and schedule constraints for your building project would be manageable. However, such is not the case with fluid flows.

Where there’s fluid, there’s Computational Fluid Dynamics (CFD). But before CFD Analysis, enter partial differential equations (PDE) on your fluid dynamics. From gas to liquid, all your fluid flow calculations have been involved with physical laws and ruled by PDE systems initially. To put it simply, PDEs help formulate problems with multivariable functions, considering the erratic nature of fluid.

What CFD aims to provide for you now is to replace the PDE systems by transforming these laws to quantifiable solution methods. In a nutshell, Computational Fluid Dynamics (CFD) is what you will get when you intersect the three branches of fluid mechanics, computer science and physical sciences.

Using CFD, we have different sets of algebraic equations. With all these output data in place, we can now further analyze and solve your fluid dynamic equations with digital computers. In retrospect, fluid is non-linear, non-negligible and often acts in a multidimensional flow – rendering it as a challenge for any engineer to calculate as compared with fixed material properties.

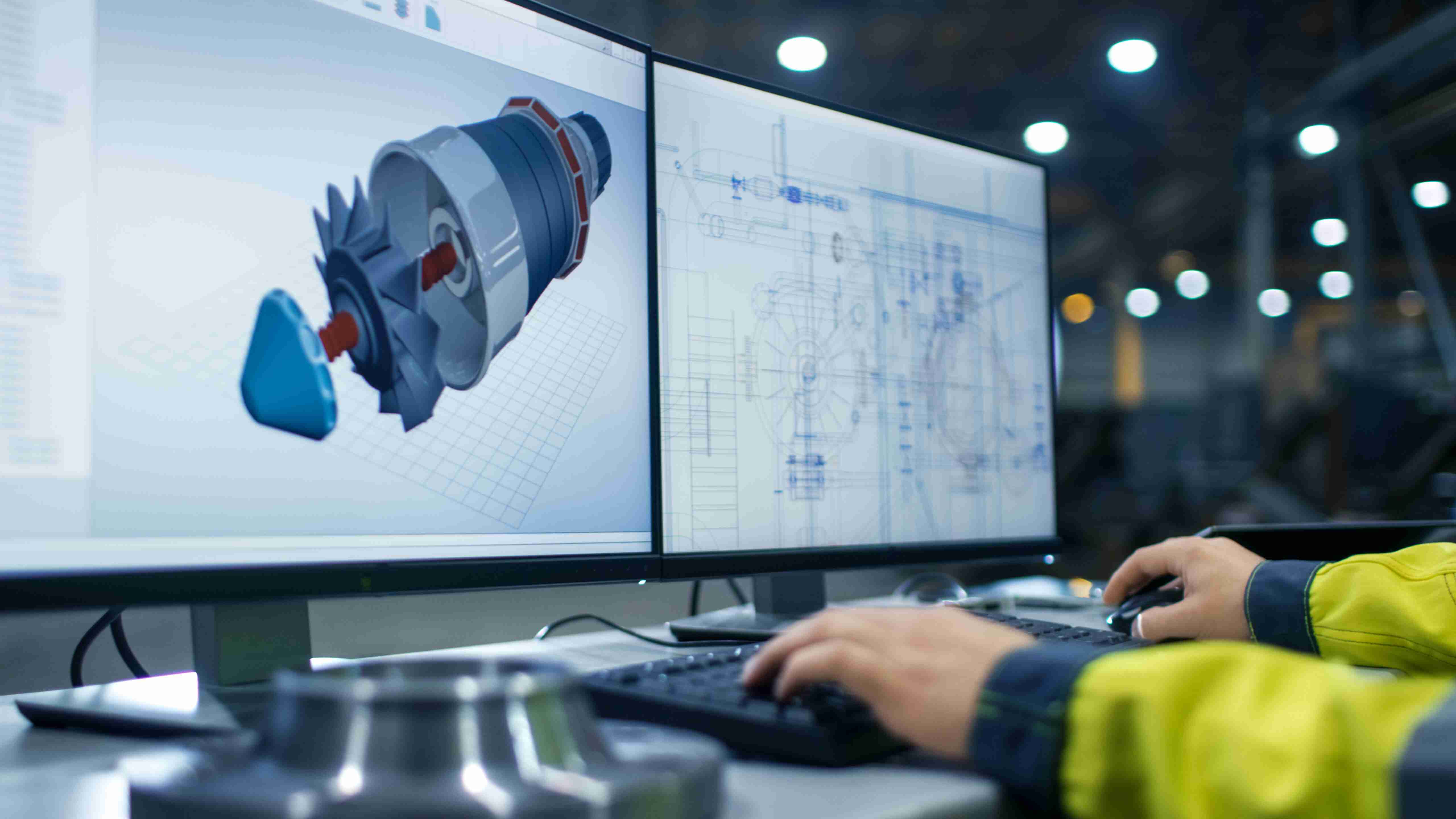

This is where Nearby Engineers New York Engineers expertise in CFD Analysis comes in handy for your project. We combine engineering with frontier technology. Whether fluid-fluid, fluid-solid, or fluid-gas interaction, our proficient engineers are fully equipped with the knowledge and tools to visualize the flow velocity, density, temperature, chemical concentrations, and thermal impact of fluid flows on all mediums.

Learn the ins-and-outs of how fluid flow works so you can better bridge the gap between cognizance and misconception. At NY Engineers, we partake on educating our clients, colleagues and industry specialists on our caliber so all parties can get a grip on how CFD Analysis can bring value to your engineering project.

In fluid dynamics, all fluid flows are subjected to unbalanced forces, resulting in continuous motion. These could range from liquids to gases, such as:

On top of real experiments, you have computer simulations when you utilize CFD Analysis for your project. Here in NY Engineers, we stack up all fluid flows against their macroscopic properties of density, viscosity, pressure, temperature and velocity.

From there, our expert engineers group the fluid flows into these classifications:

Why is there a need for classification? Our experienced engineers have put their time-tested knowledge to good use and proved that the reliability of such CFD simulations will greatly depend on such disparity. This will lead to better predictions and performance optimization when our engineers perform CFD Analysis on your engineering design projects.

CFD Analysis is right on top of our arsenal for top-tiered engineering services, and rightfully so, for several reasons. Here in NY Engineers, we transform your complex problems to simple. Conventional methods or experimental techniques are often difficult to discern, but vis-à-vis CFD Analysis, our engineers can make your life easier by providing enhanced insights on the fluid flow patterns.

To better facilitate your understanding, we provide you a quick comparison on Experiments vs. Simulations:

In totality, both techniques have their own pros and cons, but in relation to efficiency, CFD Simulations fare better than the former solution despite the iterative processes required. All the more that you can save up on your valuable resources such as time and money, which could prove to be beneficial whatever your involvement as a stakeholder in the project life cycle. This translates to cheaper, faster and multipurpose operations for you – leading to your reduced development costs, higher bottom line and business valuations.

At NY Engineers, we are fully capable of producing comprehensive design iteration process to render you accurate results on CFD Analysis.

However advanced the simulation technology may be, keep in mind that CFD Simulations are never 100% reliable, on the account of:

Case in point, this is when a professional engineering expertise could prove to be indispensable for you, and Nearby Engineers New York Engineers fit in the bill excellently. Our specialty in CFD Analysis lies in the three phases from pre-processing to solving, and down to post-processing. When we analyze the interfacing matrix of CFD, all these input and output data calculated by a computer hardware can never be produced without a baseline data acquisition from a human being.

Enter Nearby Engineers New York Engineers where we initially state the problem to be solved. From here on out, we construe mathematical models and methods through our in-depth scientific knowledge on fluid dynamics. Next, we form assumptions on the fluid flow to be modelled, and transform core concepts to discretized computer model with mesh generation.

Actual computations on discrete function values are performed by the iterative solver in this phase, where multiple solvers can range and vary according to efficiency and capability in solving physical phenomena. Implementation and debugging are performed on the CFD software, while simultaneously conducting the simulation run based on design parameters and criteria.

For the final phase, CFD simulation results are visualized and analyzed by our expert engineers. Here’s where NY Engineers can provide intrinsic value for you: our highly experienced team are armed with an arsenal of engineering prowess, mathematical ability and attention to detail. We verify and we draw conclusions based from the calculated results, all while partnering with industry-specific specialists for an interdisciplinary approach. We validate, we adjust, and we iterate. At NY Engineers, we do not stop until we get the desired and accurate results. This is your leverage.

To simplify the concepts for you, these are the main components of CFD design cycle, where countless iteration process from multidisciplinary collaborators can take place:

Complicated at first from a technical perspective, but when deduced down to comprehensive tidbits, CFD Analysis prove to be useful in almost any, if not all, industries. The wide range and extent of Computational Fluid Analysis (CFD) goes so far from energy and power generation, down to product design and MEPF services.

Some particular applications where numerical simulations of fluid flow can be useful include:

Whether you lean towards an inclination on medical, construction or automotive industry, all these practical advantages rendered makes CFD Analysis an indispensable tool. Next, we discuss how our skillful engineers employ CFD in particular with our engineering projects.

At NY Engineers, we do not impose limitations on what we can do. Our exposure in Architecture, Engineering and Construction (AEC) industry gives us a wide breadth of experience as we take on any project from residential, commercial or industrial setting.

The basic premise of our core functionality as a reputable engineering firm is to provide you expert consulting services on building and construction industry.

As engineers specializing mainly on mechanical, electrical, plumbing and fire protection services, we utilize CFD Analysis on these common spaces where fluid flows regularly interact:

When you employ our engineering service of CFD Analysis as a value add-on for your projects, you are guaranteed that all fluid flow mechanisms are fine-tuned down to the last detail. In a project life cycle, clients together with lead architectural and engineering consultants, work in a multi-faceted approach to form a coherent output.

At NY Engineers, what we bring to the table is our engineering expertise. Take HVAC design, for example. Best to know that for a proactive maxim, we conduct advanced simulations for the optimization of your HVAC design parameters. Taking occupant comfort into account, we calibrate your building’s HVAC system alongside with its location, diffusers, flow rate of supply air and more. From modifications to improvement, there’s nothing that a CFD Analysis from our expert engineers can’t do.

In general, CFD Analysis will yield you numerous practical advantages on all factors and considerations with regards to the parameters of your project. Our skilled engineers clue you in on what you can recoup when you invest in our CFD Analysis.

Crucial errors can be mitigated before building the prototype or installing the system – leading to improved performance and more savings for you in the long run. When the designs get too complex, you can lean onto the CFD Analysis for automation and optimization.

In comparison with experimental methods, CFD Analysis yields you more accurate information about the fluid flow within your occupied zone. Our NY Engineers can help you validate your results, so design development iterations can take place until you get to your desired result.

Once turned over to facilities maintenance, you can cross-check and run your systems against benchmark standards for validation. CFD Analysis provides you the perfect tool for execution.

On top of schedule and cost constraints, design process can be excruciating. Further iterations down the road can deviate you from your original design intent – leaving you with errors which could be alleviated if you chose to outsource this line of work. Tap into our analysis domain so you can divert your internal engineering resources to your benefit, without worrying about the definitive impact on your valuable resources.

Leverage our engineering expertise on CFD Analysis for your advantage, then you can take a back seat while our specialized team of engineers will do the analytical work for you. Leave the complete design control to your architectural and design experts, then utilize our in-house engineering team so you can focus and free yourself on making better decisions before implementation. Our aim is to provide you value-for-money service, and through our forte in CFD Analysis, we can encourage multidimensional collaboration resulting to lesser cost overruns, reduced project timeline and robust designs.

Comb through our industry-specific projects on CFD Analysis, and learn how we can help you zero in on your business goals by taking a proactive approach. Fluid or static, Nearby Engineers New York Engineers dare to go above and beyond the challenge. Contact us and schedule a consultation with our expert CFD engineers, and see how we continuously redefine the Architecture, Engineering and Construction (AEC) landscape.