Our engineers have years of experience in the heat trace designs. They not only focus on solving the problem but also keep an eye on the budget for you.

NYE technical staff will develop collaboration and understand all the aspects of a project to determine the best solutions that are productive in the long run.

Hire us for highly customized heat trace design service that meets all your requirements and addresses all your future goals.

Heat trace design solutions work to maintain the temperatures within different processes. It is essential for the purpose of avoiding any freeze up in a particular system. Any system can shut down if it freezes up and can also put a halt to a critical process. This can result in a standstill of your entire plant.

It is important to adequately design the systems to reduce the energy consumptions as well as the installation costs.Effective heat trace design enables you to monitor and maintain the temperature on vessels, pipes, valves, and tanks. Hire NY engineers to keep you processes working at an optimal level and prevent unwanted costs.

We are one of the fastest growing MEP design firms in the construction industry. We pride ourselves on having a fast turnaround while providing cost effective solutions. We are licensed in 50 states and are your one stop shop for all MEP design needs.

We are licensed in all 50 states!

We design to the perfection

Enjoy our lightening fast turnaround

We have completed so far!

Our designs are approved by DOB in one go

The best service experience in the market

Heat trace is essentially an electrical system that maintains temperatures of vessels and pipes. Heat trace achieves all this by using the resistant element that goes through these vessels and pipes. In most cases, it is a self-regulating polymer and it can control different wattages of different elements.

When there is an ambient drop in temperature, this polymer develops the conductive pathways that continue the flow of current and with it, the heat is produced. In case there is an ambient increase in temperature those conductive pathways will separate from each other and will allow a lesser amount of current to pass.

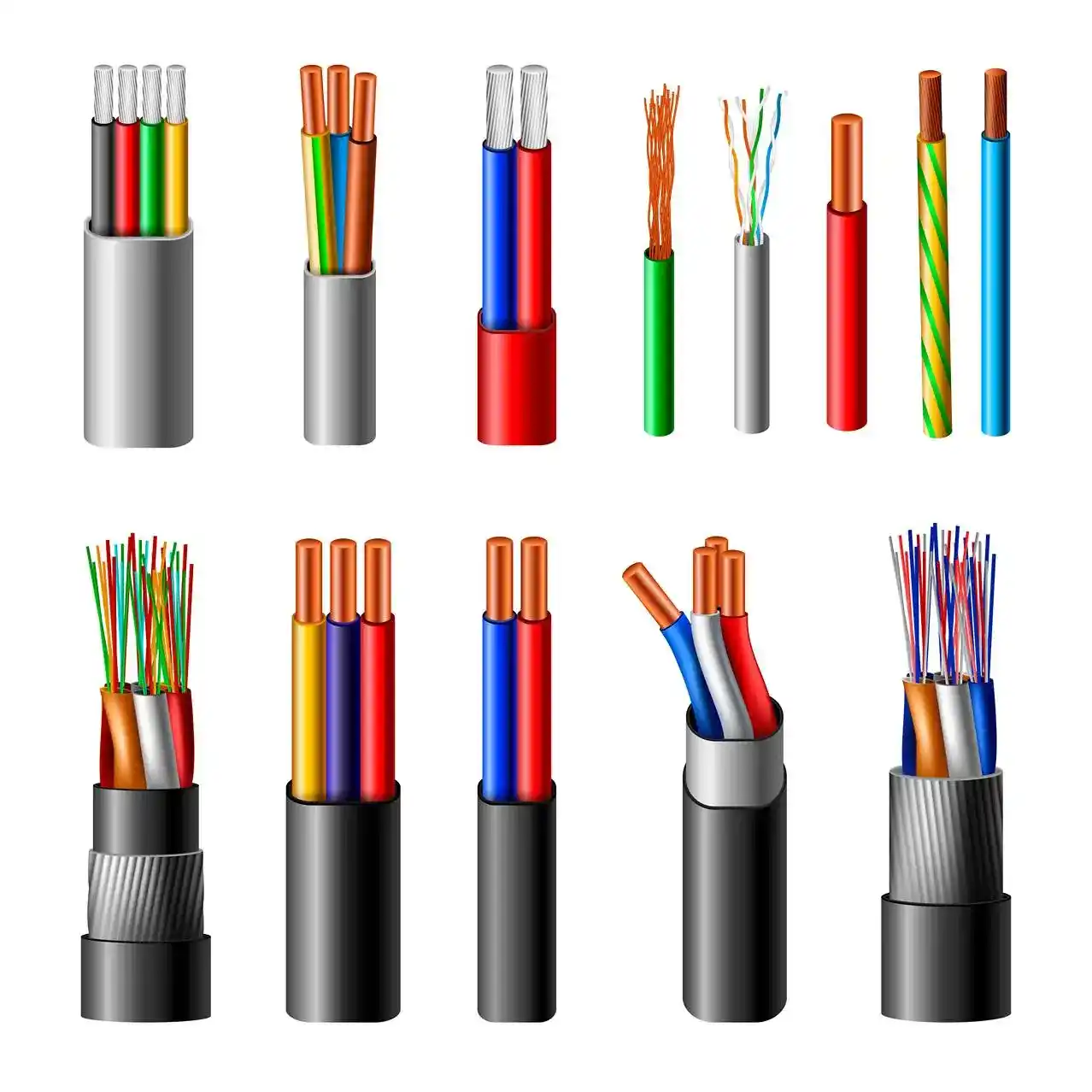

Heat Trace Calculations : It is integral to the process that the cables for heat trace need to be of the proper size for a particular application. These cables are designed in a manner that they go parallel right next to the piping and are available in different output wattages, jacket materials, and voltages.

Flanges, valves and various other components of greater mass within the systems will work as heat sinks. Therefore, the system will require extra components for compensating any heat losses. This is where the heat loss calculations come in to play their part.

The heat loss factor in conductivity and insulation thickness is the difference in overall surface area, pipe temperature, and ambiance. NY Engineers perform this calculation using sophisticated computer applications that not only simplify the entire process but also saves a lot of time.

Once the cables are properly sized, each one is selected according to the required outputs of wattage as well as the needed jacketing for different applications. For the purpose of lowering the temperatures, highly flexible cables work well. These are similar to those residential 12-2 cables. The cables for lower temperatures including HSB and PSB can only reach up to 392°F.

On the other hand, for higher temperatures the cables with mineral insulations are useful. These cables can easily withstand the temperatures that can go more than 1000°F. However, these cables are only made as per order and you cannot cut them to your required length on the field.

You’ll also find some heat trace cables for medium temperatures. These cables can withstand the temperatures that can go up to 797°F. These cables come with aluminum design and you can cut them to length on the field according to your needs and requirements.

These systems also provide a tailored solution that can easily incorporate thermostats, junction boxes, light indicators, temperature controllers as well as insulations. Most of these heat trace packages work well with the existing network of pipes but there are pre-traced bundles for tubing also available.

The Chicago Building Code has a strict compliance details associated with the heat trace systems. The reason behind that is it is directly associated with the safety of the site for the occupants. The code also provides guidance to site owners about how they can meet different requirements and avoid penalties.

In addition to the penalties, you also can reduce your maintenance costs that might result from any failures. Another regulatory authority in this regard is the NEC or National Electrical Code. The Chicago Building Code only emphasizes on these heat trace systems and discusses different penalties. The NEC is a lot more specific in this regard and it addresses various heat trace systems in its Article 427.

This article provides detailed insights on different heat trace techniques including skin-effect heating system, resistance heating systems, inductions heating, and impedance heating systems. Resistance heating technique is the most commonly used of all and this is where different types of cables are used.

Design and Pre-Installation : Our professionals understands all the requirements before the designing process starts. Our design address all the requirements and objectives as per the demand of the clients. The design also complies with the rules and regulations set by the Chicago Building code and NEC. And it must also adhere to all the budgetary discrepancies.

It is important that the heat trace design engineers make sure that all the equipment and pipes are properly installed as well as pressure tested before the tracing procedure begins. In addition to that, the area where this installation will take place must be clean of any grease, dust or dirt. It is also required that all the power sources in this area are energized. Moreover, the ends of all the trace heaters along with the kit components must remain dry both prior to and during the installation process.

Installation Process : The installation of the design begins from the circuit end as per the guidelines mentioned in the plan. After that, the trace heater must be installed in 8 or 4’o’clock position. If this position is not accessible then go for 2 or 10’o’cock position. The rolls of the attachment tape must be kept under check as well as per the length of the pipe. Under special situations, a consistent covering of the aluminum foil tape might also be required.

The installation of the temperature sensors must be at least 90-degrees away from the location of trace heaters. Necessary installation requirements must be filled when working with elbows, flanges and pipe supports as well as pumps and valves. Before the installation phase is completed run any final inspection to make sure that all the components have been properly installed and working.

Repair & Maintenance : After the installation is completed, our technicians run preventive maintenance programs frequently. Frequent maintenance is conducted to make sure that everything is working accurately. These programs also ensure that any repairs must be done before any damage occurs.

The records of all the maintenance programs are kept as a history for the purpose of tracing back to the sources of any issues. It is important to refer to the troubleshooting guides immediately if an issue is identified in the maintenance programs. After these programs are completed its time to run a check again for any issues. The reading must be recorded for each of these tests and compared with the benchmark requirements.

Troubleshooting : It is important to troubleshoot the issues that have been diagnosed by the tests. Primarily there are two root causes behind most of the problems associated with the heat trace systems.

Our team has a combined experience that spans over 150 years. We guarantee to save approximately 80% of your entire engineering costs. Our team is able to achieve it with the help of preventive redesign approach. They also make use of various components in an effective manner.

Our team of technical and design engineering professionals will provide you with an array of services the meet and exceed your requirements and demands. They won’t leave your site until they are sure that you are satisfied with everything associated with the project. This is highly important in the case of heat tracing systems. The reason behind that is it is the matter of safety of your entire plant. Hence, NYE provides a range of different services.

Surveying

If a heat trace design is available then surveying the quality of the system and its integrity. If a system design is required for a new project then our engineers will determine the demands and the goals that the client is expecting to meet with the project.

Design and Engineering

NY Engineers are professionals in what they do and for that reason, they fully understand different requirements and how to cater them. This enables them to develop a customized design that meets the needs of a particular project.

Preventing Redesigns

Our technical engineers highly emphasize the criticality redesigns in terms of time and cost. Therefore, they do their best to get it right the first time. This will prevent any wastage of time and money and will also not jeopardize the integrity of the entire project.

Install, Maintain, & Repair

NY engineers give plenty of importance to the pre-installation prep. It ensures that everything is in place even before the installation process starts. It also contributes a lot in time-saving and due to proper management, the projects complete well before the deadline. Completion of the project before time provides our engineers with some valuable time for setting any schedules for maintenance and repairs. It allows them to prevent any disruption if the current site operations.

System Integrity Testing

NY engineers will run several tests to verify the overall integrity of the system. They check for any irregularities or any prevailing issues. Running integrity tests are critical to elongate the lifespan of all the components and equipment. It improves their operational and energy consumption efficiency.

NYE also assists the clients with any of those authorizations and approvals from states governments, local authorities as well as landlords. We at NYE ensure that all the heat tracing designs meet the requirements of the regulation set by the NY Building Code and NE. This will enable you not to deal with any inconveniences associated with adherence and compliance. Reach out to us today for a pre-assessment and evaluation of your existing heat trace system or contact us for a full project management service.

382 NE 191st St , Suite 49674

Miami, Florida 33179276 5th Avenue, Suite 704 #904

New York, NY 10001